Laserology

Some thoughts about laser failures that never happened.

And about those that did.

Hey, do you know where I can buy a new

laser for my CD? It just died.

I heard it so many times that I decided to write about lasers, their

problems and easy fixes.

I looked inside over 100 CD players which DID NOT READ the CD anymore

and only one (in decimal and binary mode it is 1) had failed laser. And

that one was dead because of my stupidity. But it (my stupidity) is not

the subject of this article.

Other peoples stupidity is.

Anyway, what happens is that there is probably 20 different reasons why

the CD player does not read the disc, and people have such strong

prejudice that they all call these failures DEFECT LASER.

This is CRIMINAL because lasers are not produced anymore, and the

scarce resources left, the holy reserves - are brutally cannibalized by

people who know no better and simply buy the new units.

The top ten reasons why CD's are not read - according to "my vast

experience" in that matter - are:

1. There is a CD disk inside the player as resulting from moving to a

different house with the disc left in the drawer. Disc falls out into

the guts of the CD player and blocks the mechanism. When the owner puts

second disk afterwards - the player rightly displays ERROR.

- remedy: the first cure that springs to my mind is - open the CD and

remove the stuck CD.

2. The 20 year old belt that powers the drawer starts slipping or

breaks. After

closing the drawer - CD is not properly positioned on the spindle.

- remedy: replace the belt

3. The CD player was being used in a dusty environment and the

dust or cigarette tar settled on the laser optics. Dust causes beam

dispersion. Laser

looses focus.

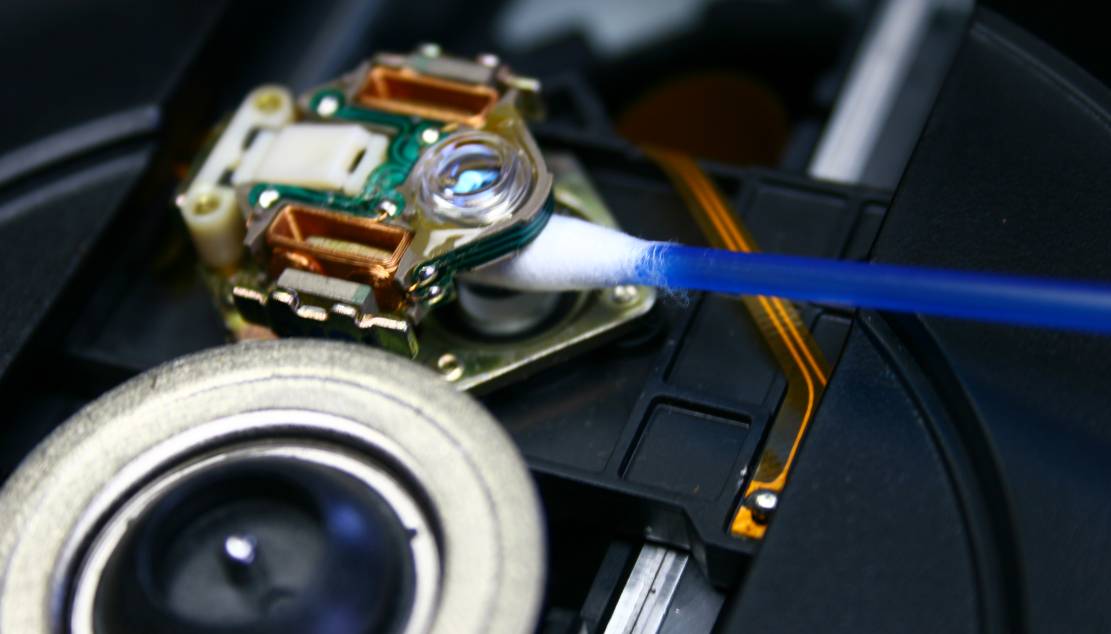

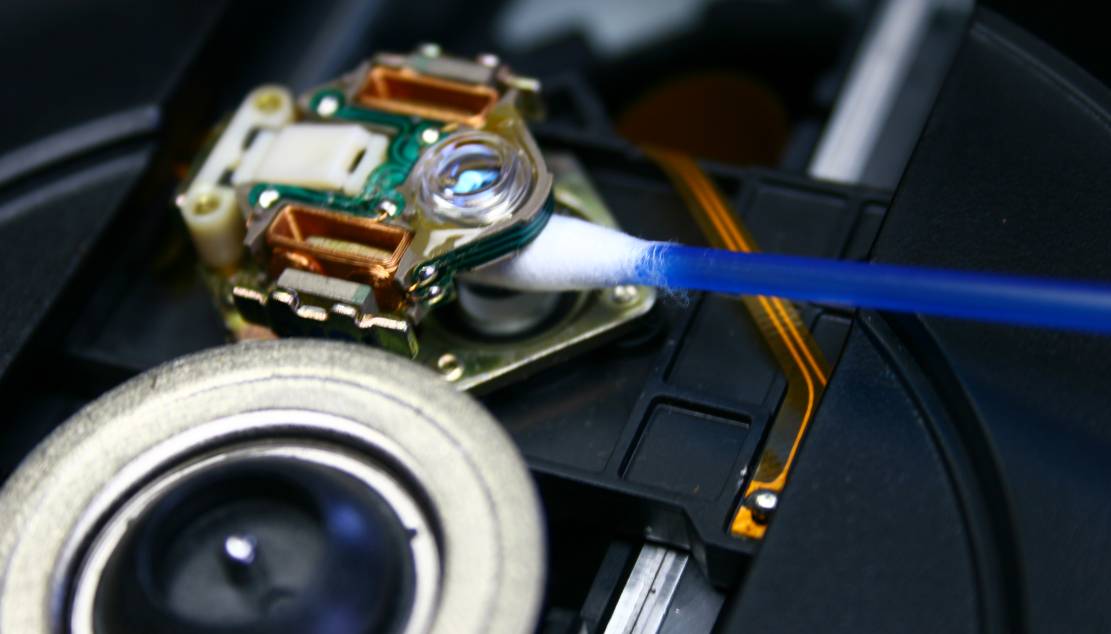

- remedy: open the player and clean the laser surface with a Qtip.

First- with wet tip dipped in the window cleaning liquid, then - dry

one.

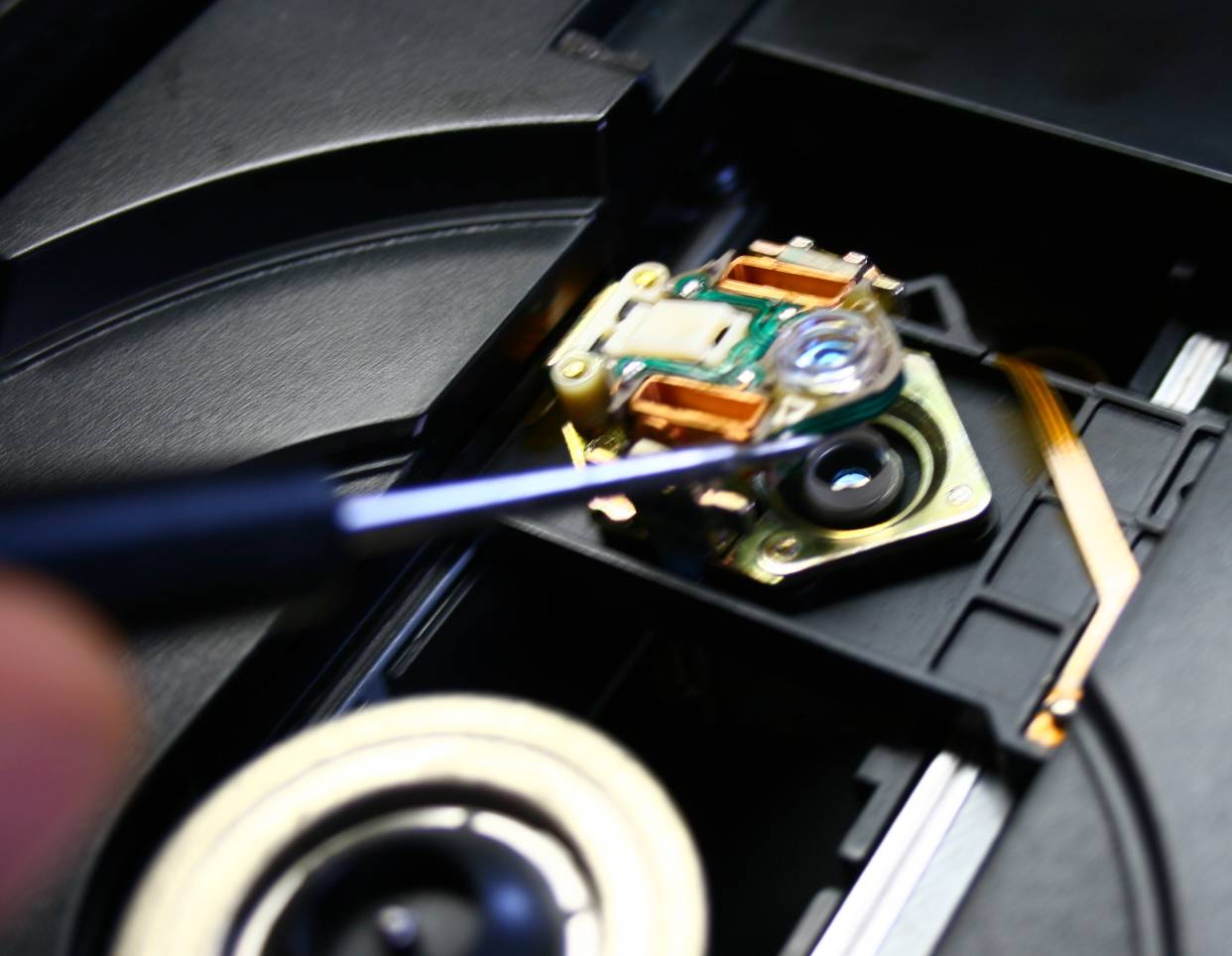

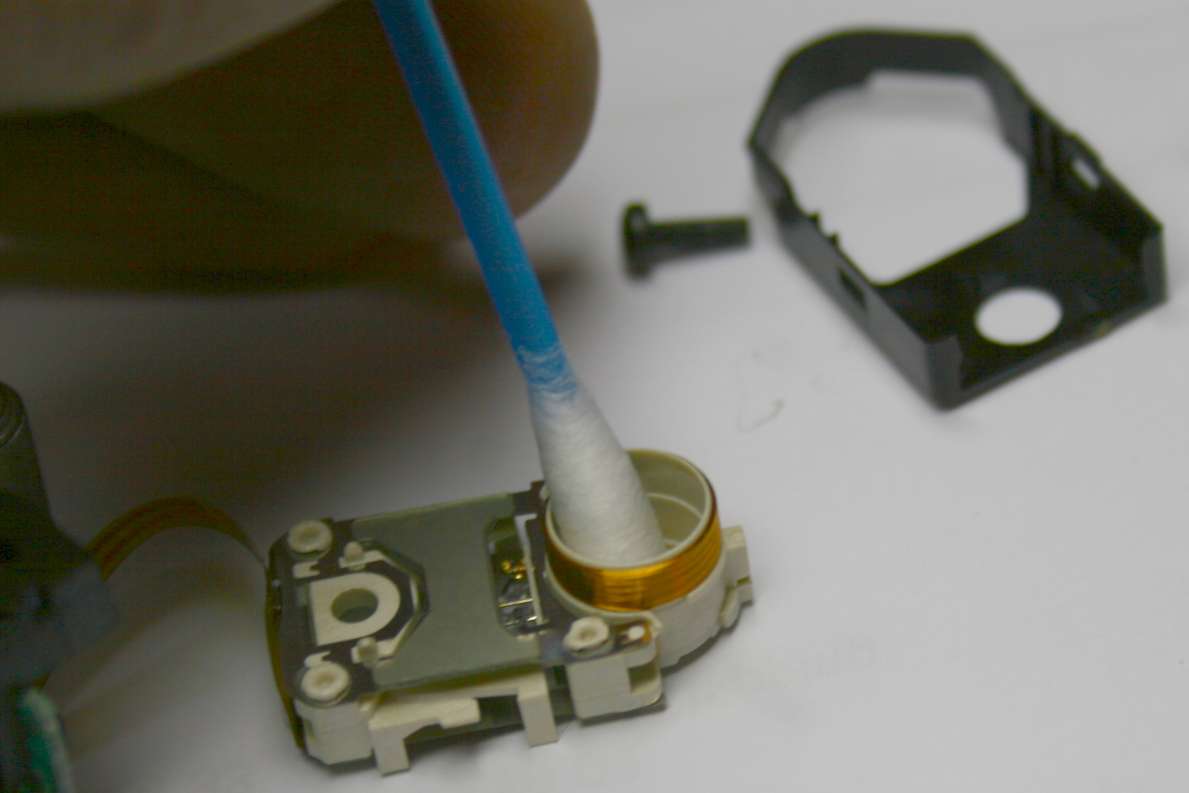

If this is not enough - clean the laser INSIDE the reading head. This

is for advanced people. Better to give this job to a watch repair man. See below - some pics.

4. The power supply of the laser circuit is defective: either too low

voltage,

or noisy, or starts oscillating from poor filtering or regulation. The

cause may be dried out

electrolytes.

- remedy: replace all electrolytes in the digital part of PCB, or

better - all of them.

5. There is a cold joint in the laser circuit.

- truth is that the solder joints do corrode and do fail. Our best

players are 20 years old and this shows. A joint which is hot, like a

leg of a regulator, or a point where the raw supply is rectified, or a

laser power controller - from the heat they develop accelerated

deterioration - mixture of oxidation, flux burning, and tin

evaporation.

- remedy - look at all solder joints, especially around laser cable

connectors, around all regulators, around places that look toasted,

brownish or cooked - and re-solder these points adding a bit of fresh

solder with fresh flux.

6. Moving cables - or ribbons - do get broken after a million bends.

Check for continuity in flexing ribbons leading to the laser, the

drawer, the motor or the tracking mechanics.

7. The tracking mechanism accumulates dirt, hairs or dust on the greasy

part and the tracking can not arrive at the center-most starting

position. With every ride of the tracking - the dirt is pushed away and

forms a sort of a "bumper" that stays on each side of the shaft.

- remedy: clean the tracking shafts, axis and rods at their extreme

ends.

8. The main motor is not keeping the right speed.

- it will look like the laser can't read, but it is simply the wrong

rotation speed. May be caused by CD slipping on the spindle, or motor

defect, or something blocking the CD like audible friction against the

surface of the drawer. For instance - the spindle can

wear off its bottom bearing and the whole CD will be lower by 1/10th of

mm. The laser will loose focus and the top clamp will not press hard

enough. In any event - the spindle must be brought back up this 1/10th

of mm.

- remedy - if the motor is just a normal Mabuchi for 5 bucks - replace

it. If it is a CDM or KSS Magnetic series with brushless motors - just

adjust the spindle height.

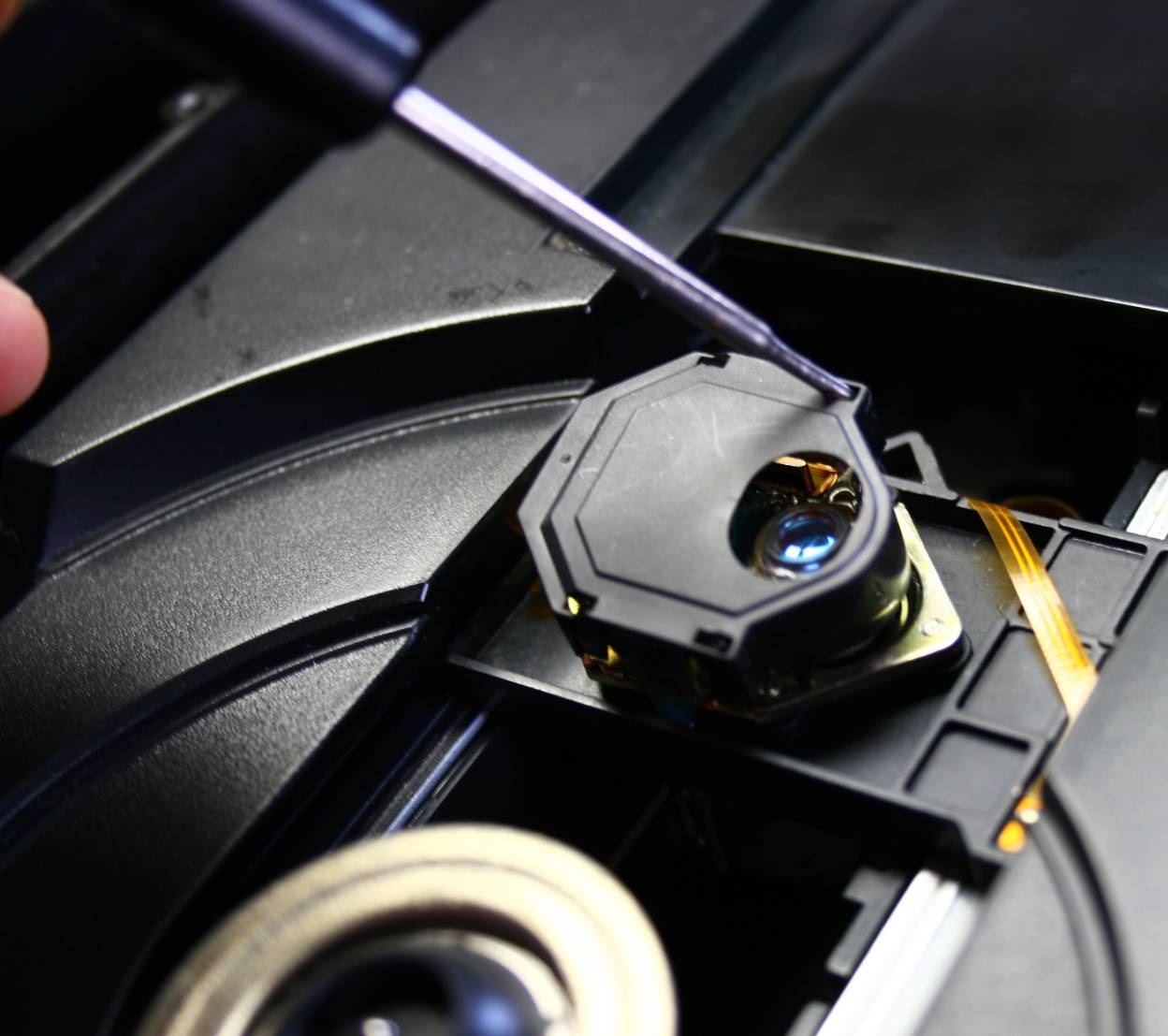

9. There is a hair or something else inside laser focusing mechanism

The laser can't freely move up and down. Since CD is strongly

electrostatic - it attracts hair, dust and animal furs. During

playback

- these can get caught under laser focusing suspension.

- remedy - remove the obstacle.

10. The CD does not spin.

After closing the drawer nothing happens and defect is displayed. It

maybe just the result of not spinning at all. The CD behaviour must be

observed - so the top cover must be removed.

CD laser diagnostics - a quick guide

Is CD laser really dead ?

Without specialized equipment we small mortals can diagnose the problem

pretty well and save tons of money on service.

Or even new laser purchase. Or even a new player.

1. Open the player's hood

2. Put the original factory made CD with clean surface and press drawer

CLOSE button.

3. Does the drawer close fully?

4. If 3 is yes, then does the CD spin at all?

5. If 4 is yes, does it spin for 2-3 seconds or for over 10 seconds?

Does it spin VERY FAST like crazy or with somewhat controlled speed ?

6. If the 5 answer is - controlled speed and 2-3 seconds - the laser is

alive and it can detect the beam reflection from silver surface.

Tips: if the laser is dead, the CD will not spin at all. The CD motor

has a

signal to start spinning only after the laser heads reports: "reflective surface detected on the height

where CD is expected to be ". However, as someone rightly

pointed out, some servo mechanisms will try spinning without checking

if CD is in place or not. Apparently, they made assumption that a small

motor spin in vain will not hurt.

7. Does the display show after 3 s of spinning the correct number of

tracks and time ?

If the CD was spinning but can not show time - it means it could

not read the TOC - famous Table Of Contents. So the laser head was

seeing the disc surface but could not read the first line of data. This

first line is at the very center of CD disc, so the tracking of the

laser

assembly must be on position "center most". The inner-most position. So

if we have a tracking problem - we cant move to the very center and TOC

cant be read.

8. If the TOC is displayed correctly but the PLAY does not happen - it

means that:

- laser is OK

- TRACKING does not move the laser from first "groove" of the disc to

another. Then go down to tracking problem chapter.

9. The CD starts to play, but skips

- observe if it skips forward or backward. If there is a mechanical

problem - the advance of tracking is blocked - the skipping will happen

backward. If the tracking controller is too enthusiastic - it will skip

forward.

Adjust the physical levelling of the CD player, and adjust the tracking

gain

(see below).

10. The CD plays well the factory CD's but fails on the CD-R's

The laser focus on CD-R is different than in factory CD.

The pit reflection is also different on these two CD media

The amount of plastic film that protects the metallic layer in the CD

and CD-R is very different.

Generally, it is always easier to read the CD than the CD-R, no matter

how good is the blank media and how slowly it has been recorded. Not to

mention the no name CD-R

recorded at 24x.

So if the normal CD plays well and the CD-R plays faulty (distorts,

skips a lot, reads slowly or not at all) there is probably a problem on

the horizon. The system is already too weak for CD-R but still somehow

manages on regular CD's.

This common problem can be a result of any other problem listed above

- dirty laser, bad adjustment, worn out spindle, slipping disc,

slipping belt, anything really. INCLUDING of course - a dying laser.

All slowly

building-up problems show on CD-R's first, months before CD's will show

same problem.

Problems 9 and 10 usually get worse as the laser is further away from

the center - meaning - on higher number of the tracks. If it starts

skipping on track 4, it will probably very badly skip on track 10th and

never ever reach track 12th.

11. Lasers which die on players bought 2 weeks ago from E-Bay

If the otherwise excellent, pretty and valuable mint player starts

having laser problems at the original owner, it will inevitably end up

in the hands of the

laser guru, who will turn up the power of laser emission. It may help

the laser to read better TEMPORARILY.

Then the guru gives the player back to the owner and says: " well, I managed to help you, the bill is

200 Euro, but take my good expert advice and start looking for a new

player. This one will not last long. Sell it quickly, while it

still works okay.

Then the owner goes home, and he freaks out. Gee, if the adjustment

costed me 200 Eu, how much is gonna be next time around, when the big

un

strikes ? So he puts it on ebay with a story attached about the uncle

who passed away and while the nephew was cleaning up his house this cd

player was

found. (Funny that these houses always get cleaned by the

nephews not sons or wifes) It was

always well taken care of because the uncle was a music

lover. He only listened to it occasionally - one opera CD every sunday

after a

mess. It is sold as it is, without warranty, because the young

nephew is too busy to check it. "

That is how mint collectors players end up in the hands of happy

new owners only to die 2 weeks later.

If that story is familiar to you - the laser is REALLY DEAD. A

dying laser with cranked up emission will die very fast.

Example of Sony

KSS151A laser deep cleaning procedure

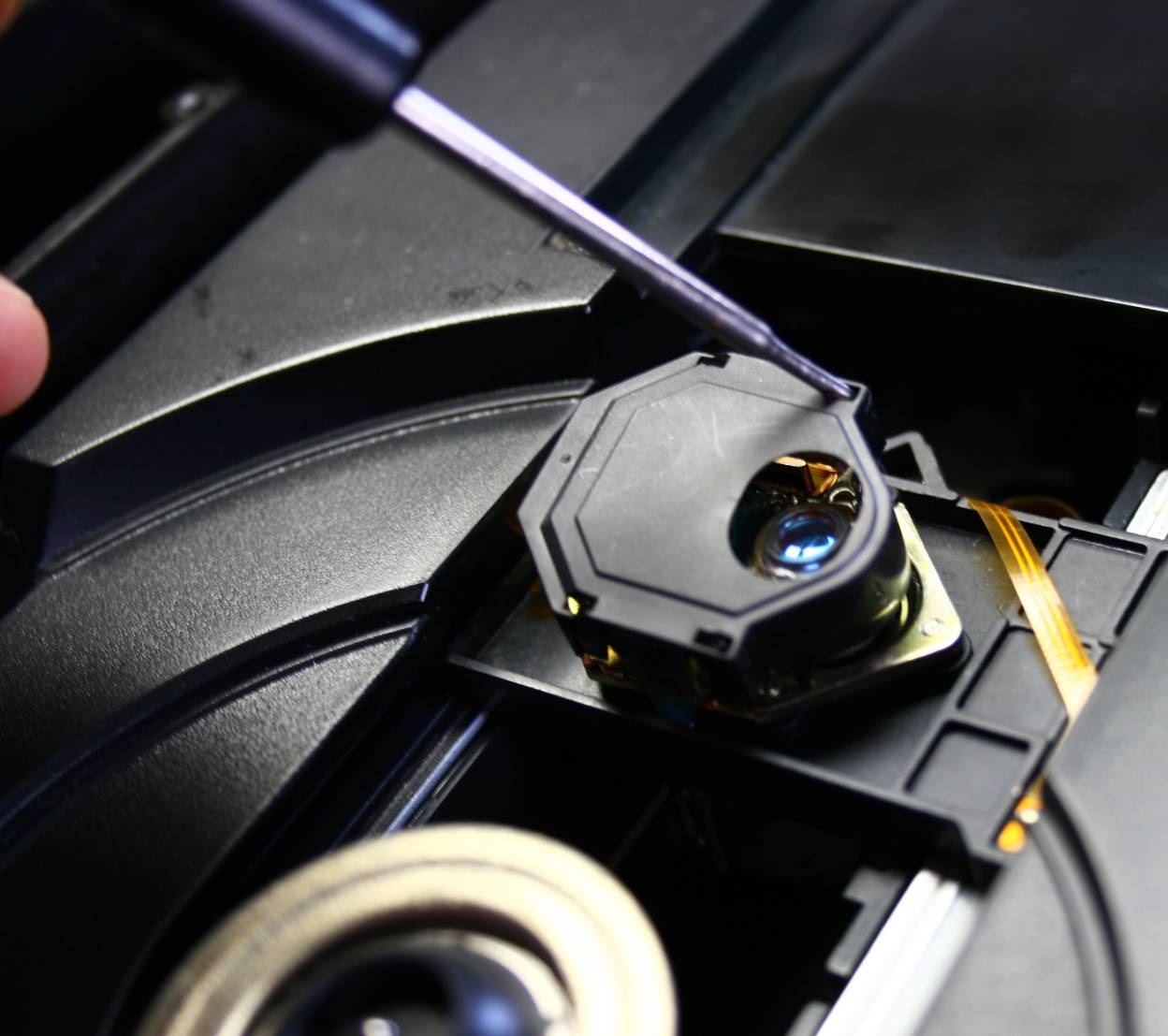

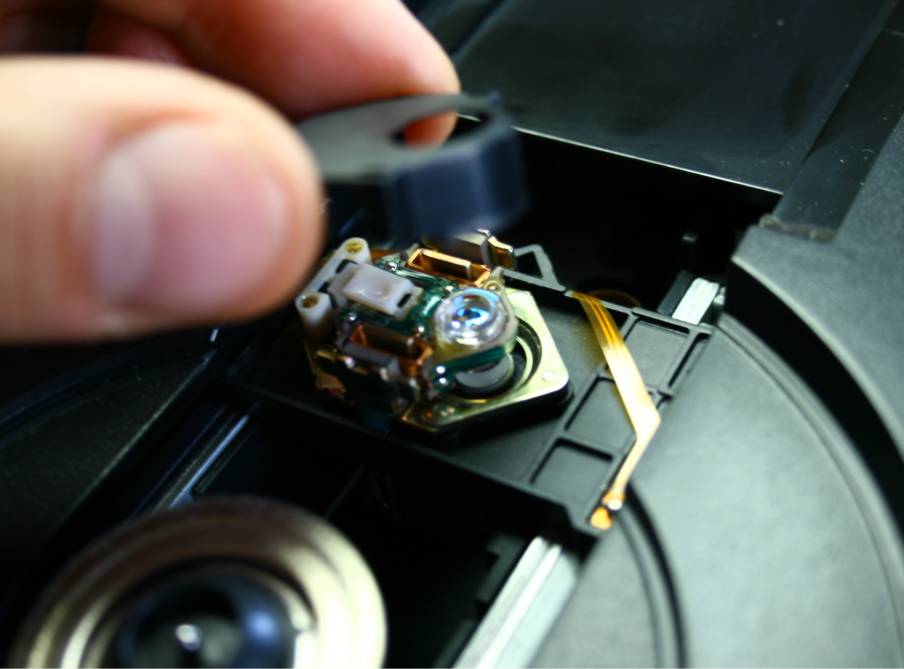

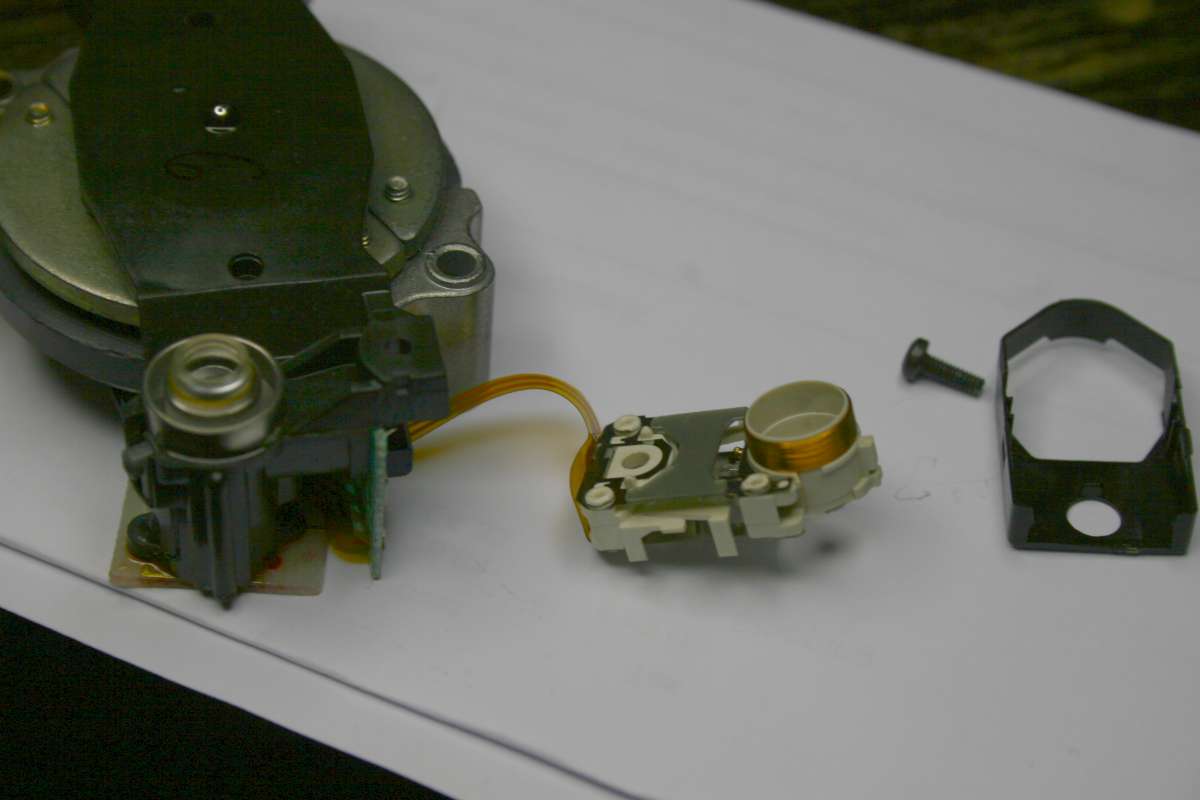

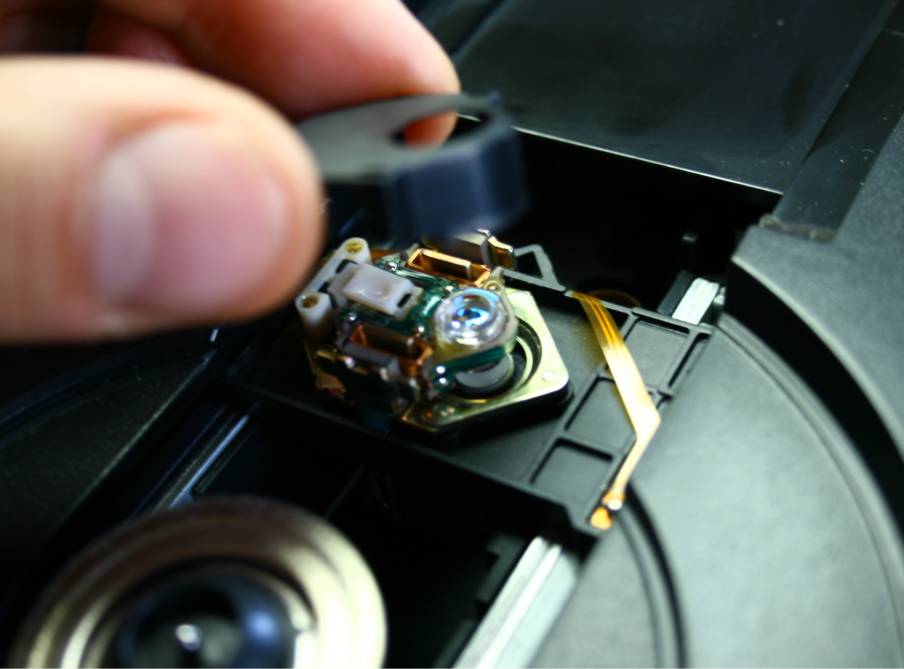

The laser protection cover must be first removed (Example of Sony

KSS151A, similar to all other Sonys.)

The upper lens can be gently lifted up by 1 cm or so.. Be GENTLE.

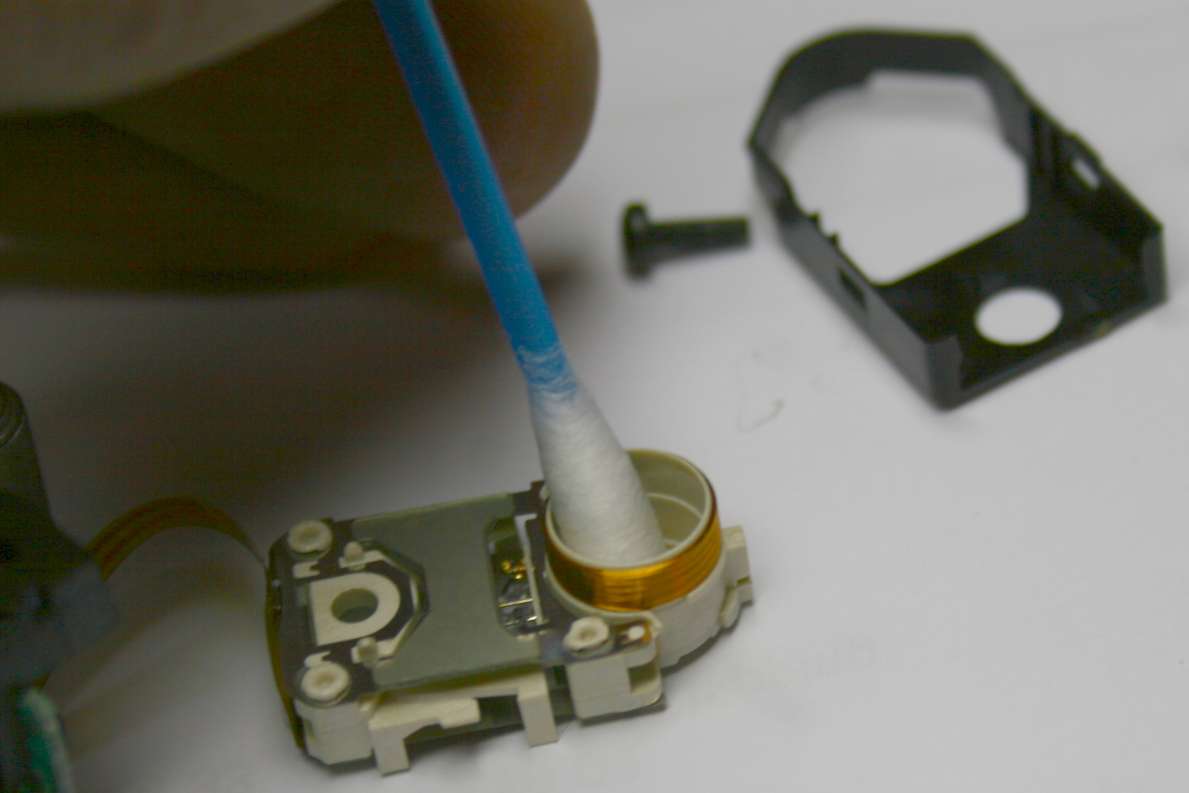

laser cleaning

My Q-tip cleans the lower lens. But please use NEW q-tips, without ear

wax on them.

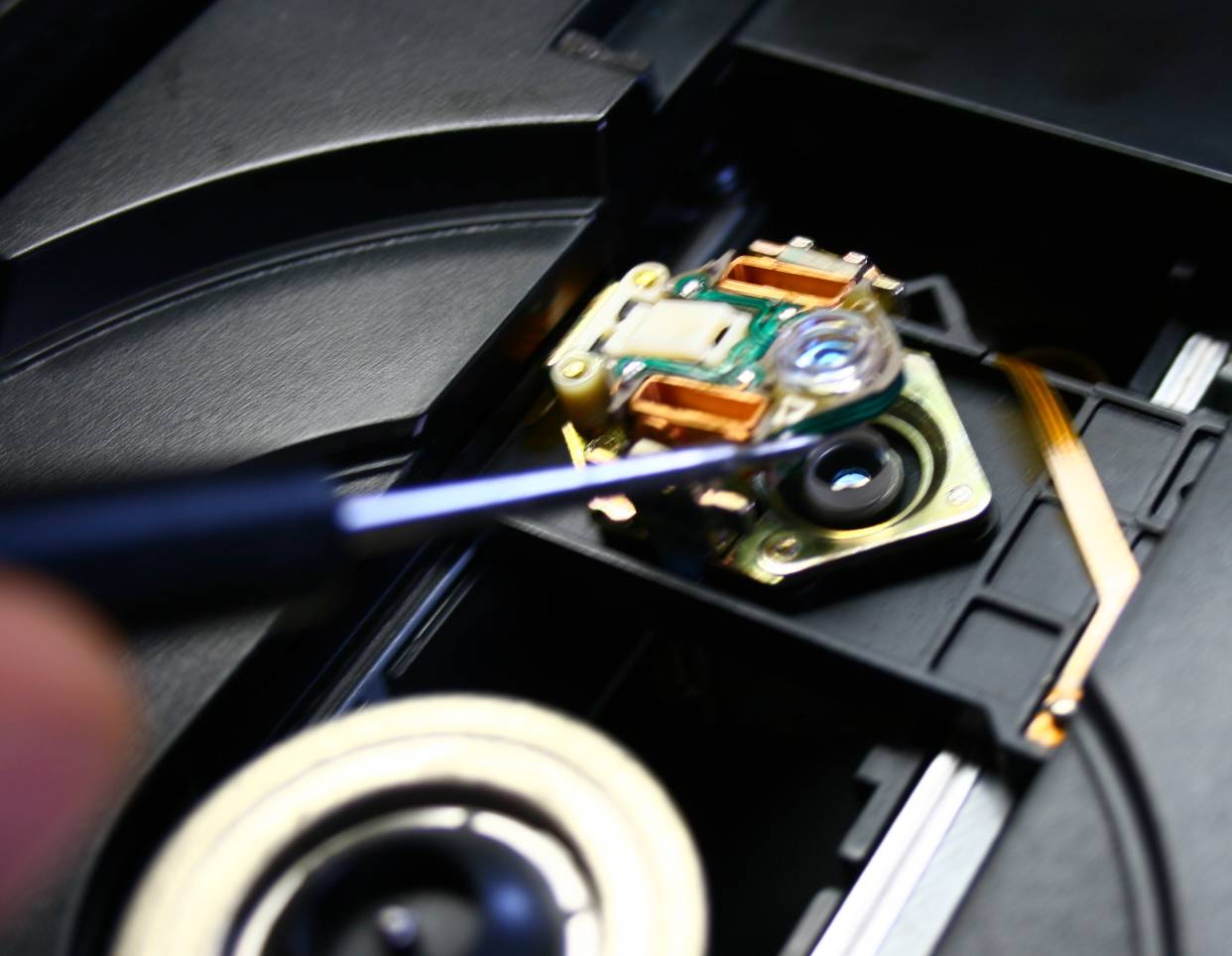

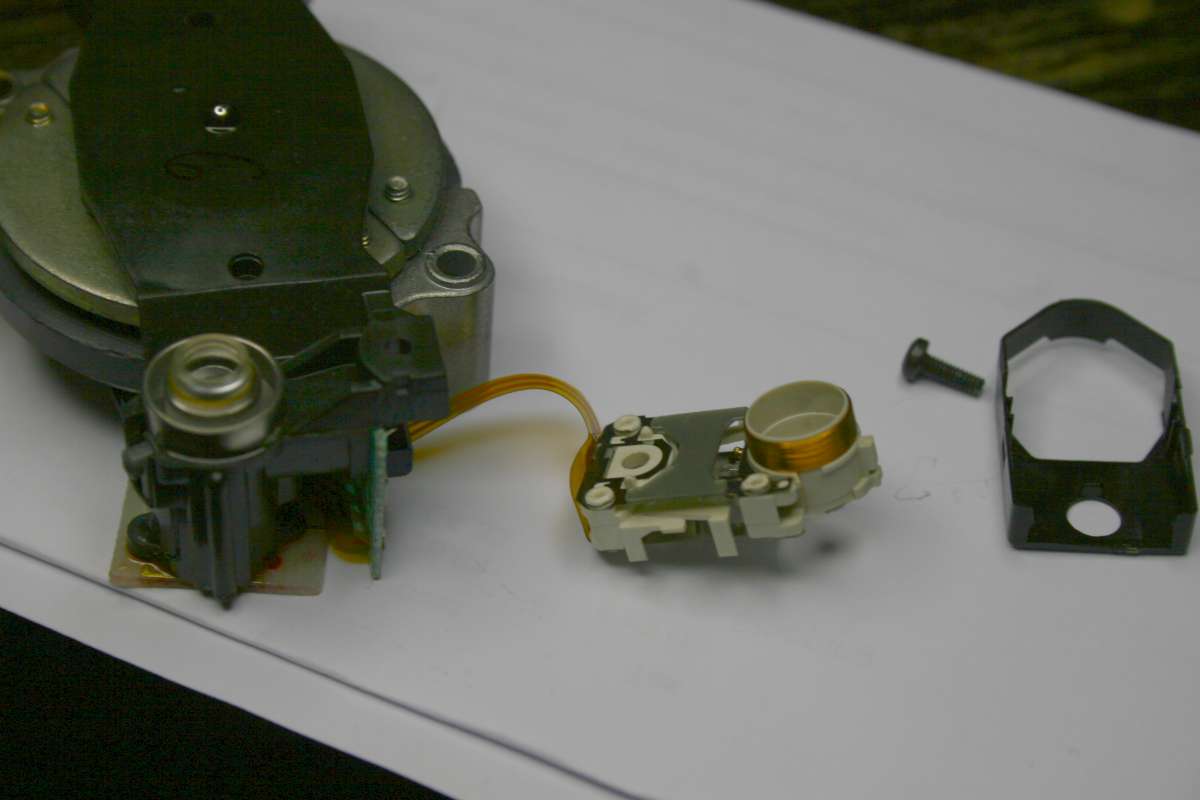

Cleaning CDM1MkII, CDM2, CDM4 fro Philips

The upper lens can be safely removed by unscrewing the screw that holds

it.

Underneath we find second lens - this one non-removable. We can clean

it.

We can also gain access to clean underside of the upper lens.

True indication of a dead laser circuit (not necessarily the laser

itself)

If you observe the whole CD starting procedure with player's hood

removed

- and after

properly loading the CD in the position - the CD does not spin at all -

there is high probability the laser is dead.

Turn off the light and repeat the drawer closing process WITHOUT any

CD. Look at laser: does it emit red beam - does a VERY tiny dot inside

the

player lens blink? It is activated only during the first 2-3 s

after drawer closes, and always during the lens focus movement up and

down.

(of course do not look too closely or straight - just a glimpse from

the angle is enough)

If there is no red dot - no laser emission. But maybe it is the circuit

?

Another thing to check - providing the red dot is present - does the

lens move

up up and down repeatedly 2-3-4 times? It is a process where the laser

tries to catch focus on the reflection from CD. If the red dot is there

but no focus movement - the focus circuit is dead. Still - no need to

replace laser. Check it with no CD - just open and close the

drawer to initiate the focus movement procedure.

If the laser moves focus lens up and down and it finds reflection - the

motor of the main spindle will get the instruction to turn clockwise.

If the laser beam works - chances are high - the player can be repaired

to

serve you again.

Electrical circuits of the CD reading process:

There are four circuits that are responsible for the whole process.

Each one has adjustments and it has own dedicated power control chip.

The power control chips often fail in Sony machines. They can be

specialized chips, opamps or transistor pairs.

The power control chips in turn are managed and controlled by

servo processor which

gives all commands and checks if all is OK , it is called the logic. It

also decides about

problem management: should I keep trying, and when to give up.

Circuit No. 1. Laser focus - controls electromagnetic motor suspending

the laser lens on the right height.

Circuit No. 2: Laser power - controls the emission.

No. 3 is tracking gain - which controls where the rails should be

relative to the CD tracks.

To check the circuit - open the player, without any disc - move gently

with your finger

the laser assembly to off-center position while player's power is

OFF.

Turn the power ON and see if the tracking will bring the laser assembly

to the

center-most position. If not - the tracking is fucked up.

No. 4 is the reading circuit - the laser beam is being read by the

photo diodes and the data stream is being formed.

Needless to say - there is also the motor speed control circuit.

On the more highend machines like KSS151A, KSS152, KSS190, BU1, and

other large and heavy HAAL motor magnetic rails - the power to

move the

mechanism (tracking) is relatively very very high. Much higher than on

the mechanisms like modern DVDs, PC readers and play stations where the

tracking is done by a motor with snail gearbox. The circuits that

send huge

current to the electromagnets are very big, their transistors and chips

get hot, easily fail, and also burn out solder under their own solder

joints.

These machines were gorgeous when new, but after 20 years may fail.

CD laser transplants

Well, I am not a big fan of laser transplants. Unless you have

IDENTICAL laser - it may be difficult. This is doable for very advanced

technicians. I am not experienced in this department.

CDM0 and CDM1 are probably possible to cross transplant. A donor in

good shape is hard to find though.

These two are probably the best lasers and best mechanisms ever made.

Especially their lasers which belong in military rocket science - real

multi lens glass type ones.

The CDM1 MK2 is in fact not a newer MK1 but it is a CDM4 in pro

version. (meaning - with metal cast sub chassis) The transplants from

CDM4 to CDM1mk2 are supposedly successful

and worth the hassle.

Donations the other way around would be stupid.

The CDM4 is very popular and easy to find, but there is - I counted -

over 5 variants that do not cross breed easily.

The most popular ones are CDM4/11, CDM4/19, CDM4/21, CDM4/25 and

CDM4/44 if memory serves me.

CDM2 is a bad mechanism that fails a lot and is probably compatible

with CDM1 MK2 and some CDM4

's but don't take my word for it.

CDM9 is alone, no twin brothers, sorry, but it almost never

fails. I love it.

CDM12,x and VAL12,xx and VAM12,xx are available on the market as new

for 20 Euros or so, so don't bother to seek laser donors.

CD PRO from Philips is so rare that I have no first hand experience. It

probably is as good as it gets.

Sony cheap ones like KSS213, Kss 240 and so on - exist in plenitude on

after market.

WARNING: a man of knowledge told me that there are NO GENUINE spare NOS

lasers or mechanisms on the market today - all of them are either

factory rejects or copies. It does not mean they are bad - not at all,

but they nevertheless are NOT GENUINE. This applies to both Sony and

Philips units. Chinese factories make tons of lookalikes.

Links to sites about CD lasers and mechanisms:

When looking for a laser transplant - the first place to visit is

Vassili list of players to see the possibilities of donorship.

http://www.vasiltech.nm.ru/files/cd-players/CD-Player-DAC-Transport.htm

- list of DAC and transport

There is also this cool laser list - incomplete but at the same time -

very detailed for some manufacturers:

LASER LIST FROM JAPAN

There is also a must read web site from Netherlands at the Vintage

knob service.

interesting read about CD history:

http://news.bbc.co.uk/2/hi/technology/6950933.stm

About the RED BOOK

http://www.nationmaster.com/encyclopedia/Red-Book-(audio-CD-standard)

WIKI

http://en.wikipedia.org/wiki/Compact_Disc

http://www.answers.com/topic/compact-disc-player

Adjusting the CD mechanism adjustment pots

Oooouuugh this is a tough subject.

If I advice you to turn these pots, I will end up being forced to

answer 10 000 emails begging for help.

My advice is NOT TO turn the famous pots which adjust the laser, focus,

tracking etc. But you will do it anyway, I can't help it.

All I can say, that after fixing 100 player lasers - I know how to do

it and THAT'S WHY I know I should beg you not to try it at home.

However, if you have a dead player, and you read all the above article,

and you think you have nothing to loose - try turning the pots.

FIRST MARK THEM WITH MARKER PEN TO BE ABLE TO RETURN PRECISELY TO THE

STARTING POSITION. Your wife's nail lacquer is a good alternative but

leave it to dry.

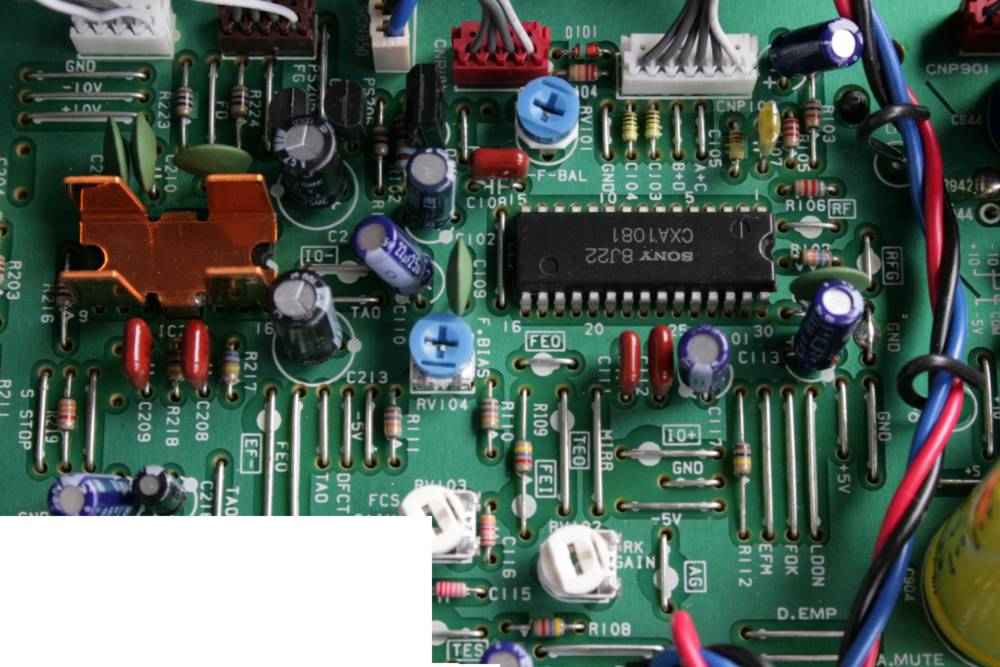

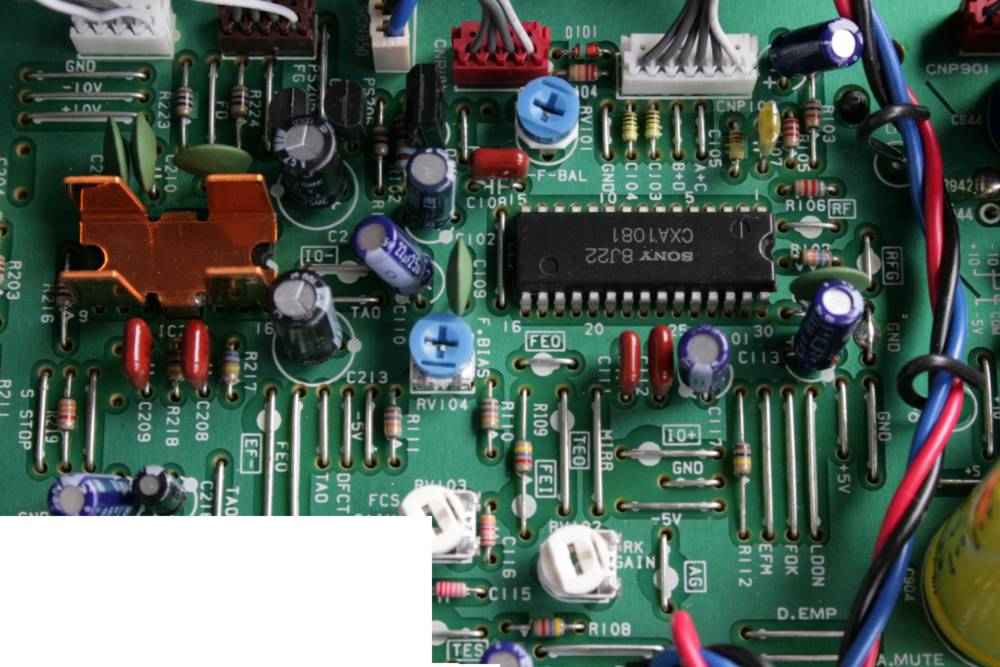

After marking, read the descriptors on the PCB silk-screen:

Philips uses 2 pots - one for focus one for tracking.

Without manual you can identify them because when you observe the laser

lens while turning the focus pot - the lens will also move up and down.

The Philips pots are adjustable with hex allen key

Philips machines like CDM are usually easier to adjust than Sony breed

- with their 4, 5 or even 6 pots. But in Philips machines these pots

are usually hidden below the transport. That's too bad. Sony allows us

to turn easily while playing.

Sony Machines have descriptors marking the pots: FG (focus gain)

FB (focus bias or balance) TG - tracking gain and TB - Tracking balance.

There is also absolute power adjustment and one more which I cant

remember.

If you don't mark the starting positions with pen - finding the G spot

again will be as possible as winning the lotto. Don't even try it.

Only turn the pot responsible for your problem: focus for focus,

tracking for tracking etc.

In 90 % of cases the pots are OK in the center position. If the pot

must go (or it is already) in extreme position - it is an indicator of

big trouble.

note the blue pots are for focus, white for tracking, and the copper

radiator is for power control chip. The micro CXA1081 provides the

servo logic. Actual photo from Sony 227ESD player which has magnetic

rails tracking and KSS151A laser.

WARNING: Each time you move any pot - the drawer must open and

close to reset the setting memory of the servo.

So any change of pot must be followed by the drawer opening cycle.

There is also a technique of finding the pot position by ear - mis-

adjusted mechanism make noises like constant focus-finding noise or

tracking skip noise. You can HEAR the laser being unhappy. If all is OK

- the laser system should be silent and quiet at playback. Listen

carefully to the laser while turning the pot.

Having said all that - avoid opening the Pandora's box of pot turning

process

at any cost.

If you are so stupid to ignore my warnings - it is THEN when you will

really fry the laser and you can really report it dead. Dead DEAD.