capacitors

Capacitors are some of least understood components in all Audio World.

After getting 10 000 e-mail - I can tell you.

Everybody who knows what STEREO means also knows, that capacitors are important.

The Holy Truth about capacitors is

that:

1. Capacitors are important and must be changed immediately

2. Very Expensive Capacitors are better than cheap ones

3. There is always another capacitor that will be better than the

current one

4. If nothing else helps - bypass one capacitor with a better one and

it surely will be sounding like everybody get out.

Lets try to demystify capacitors and find out the real gems in the

heap of dog doo.

PARAMETERS

Every Audiomaniac knows very well the capacitor parameter nomenclature.

Every magazine, every audio forum and every guru reviewer will tell you

that main parameters of capacitors are : SPEED, Brightness, Slowness,

Dullness, Clarity, Musicality, and furthermore they are characterized

by BURN IN PERIOD.

Knowing the above parameters we can decide if the capacitor is a GOOD

ONE or a BAD ONE. It is almost an Izzardian definition of a BAD DOG!

Maybe I have slept through the capacitor class, but I know

nothing about the speed of capacitor. Except when it is thrown

out of the window - its Velocity V equals g x t

Capacitance

Capacitance is a measure of how many electrons the capacitor can store

and hold at a certain potential versus the reference electrode. The

smallest unit we use is a picofarad, followed by 1000 times bigger

nanofarad, and 1000 times bigger microfarad, followed by 1000 times

bigger milifarad.

Ridiculously, a microfarad (uF) is the most popular unit and

people

love it so much, that they came up with something as crazy as 10 000

uF. Almost like a mili-kilometer. Or kilomiliwatt. Anyway,

nobody uses a measure 10 miliFarads but this crazy 10 000 microFarads.

Is capacitance important ? Is the bigger the better ? - The magic

answer is - IT DEPENDS - so please read on.

Voltage

NOTE: voltage parameter of caps does not play in circuits. It is

indifferent. Caps sound and behave regardless of voltage . It is only

about safety. The circuit electrically does not see this parameter at

all. (unless the cap breaks hahahaha)

Voltage is the second parameter written on the cap. What does it mean ?

Voltage is the maximum potential between cap electrodes which is

guaranteed by the manufacturer not to BREAK. Probably caps have high

safety margin, but we DON'T WANT TO TRY how high we can go before a cap

breaks. Usually, cap breaking SHORT has absolutely catastrophic

consequences so we tend to use the caps well UNDER the nominal voltage.

The trust in capacitor voltage as being true, really guaranteed and

protected by safety margin is proportional to price, brand reputation

and age of production.

A no name electrolyte made in 21st century will likely break or explode

even 5% above nominal voltage.

Old and branded caps used to be specified well way below the real

safety line. They made them rated prudently and with consideration to

break consequences. We like that. The circuit designers back then could

really

use 400 V caps in 400 V circuits, without adding their own margin of

safety.

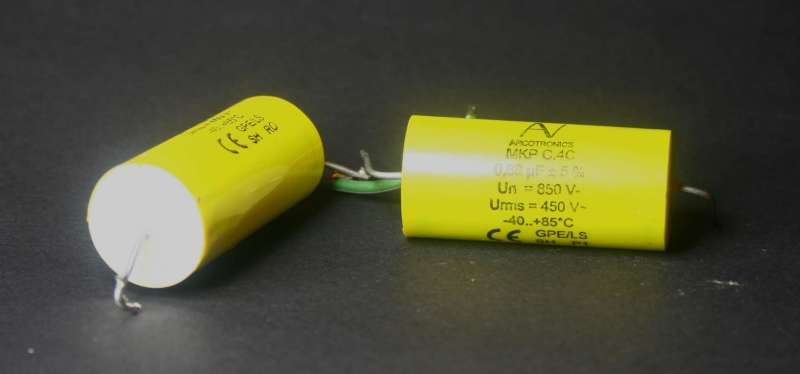

FOIL type capacitors which are ALL NON-ELECTROLYTES usually start at 65

V meaning that there is no cap rated lower than that. Usually even thin

dielectric foil will withstand 400 V easily.

Is it OKAY then to use a 400 V cap in a signal decoupling function at

the

op-amp output which has merely 2 V DC offset and 1 V pp signal ?

YES, as long as the size does not scare you.

Quality

In the world where electricity is not taught by the hi-fi reviewers or

audiophiles or journalists (that's where 95% audiophiles get

their

electricity ABC) , the real quality of capacitor is characterized by

the mix of 3 or 4

parameters. Main parameters are:

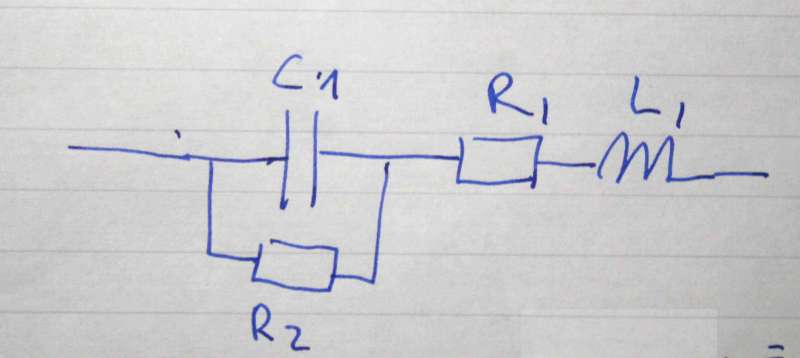

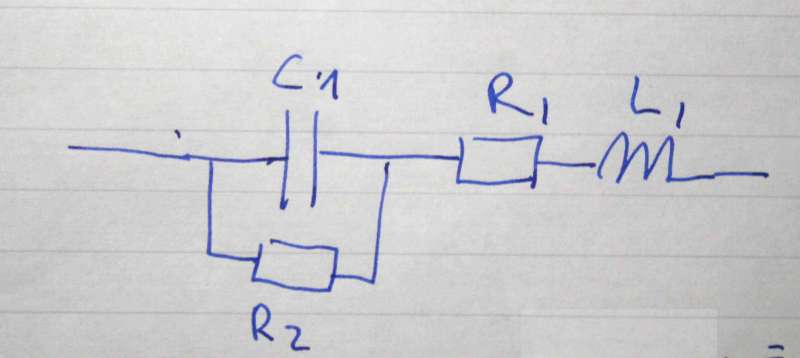

DC Series resistance = leakage (R2) = ability of cap to block DC

current.

It is usually above megaohms. or tens of MOhms. The higher the better.

Usually - not an issue at all.

ESR - equivalent series resistance for high frequencies - it is a

very misleading term - the

inductance for the

uneducated people and in fact ESR is a poor man's IMPEDANCE. As we

know -

impedance is a sum of inductance and capacitive reactance and is

FREQUENCY DEPENDENT.

Here we arrive to the critical point of quality issue: capacitors due

to not negligible inductance have RISING IMPEDANCE VERSUS FREQUENCY. So

a cap behave like a "pure" cap at 1 kHz, but at 300 kHz it is another

ball game - it behaves like a cap with a 100 Ohm resistor attached to

it

in series.

Most caps - even poor ones, behave like perfect caps to say 100 kHz.

QUESTION: Is it good idea to place a golden Mundorf in bass speaker

filter ?

Answer: bass filter works in the domain between 80 and 500 Hz so ANY

CAP will do.

Q2: Is it important to put Mundorf Gold in series with Alpha Core coil

and 3 Ohm resistor in midrange speaker circuit?

Answer: NO, because the WHOLE QUALITY thing about the Mundorf is it's

low series inductance and by connecting it with a coil which has

inductance 1000 times bigger than the whole cap - we make the whole

quality point INVALID.

Equally the whole quality point about Alpha Core Flatfoil coil is it's

low DC resistance, so by putting it in series with 10 x bigger resistor

we

behave like fools.

Equivalent model of a real world capacitor - which includes besides

the pure C - also some R, some L and some more R.

Lets remember this: high performance (expensive) capacitors belong in

circuits where there is NO OTHER INDUCTANCE OR RESISTANCE IN

SERIES with them.

If a cap is bad because its L1 is 0,1 mH, and a good cap (expensive)

has L1 below 0,01 mH, why buy the expensive cap if the circuit contains

series coil Lx with 2 mH ? The money for 0,01 mH cap is not wisely

spent.

One case example is a power cap to the ground - this is designed to

pass to ground the noise, and keep the pure DC at the electrode.

Another factor of quality is mechanical integrity - which is related to

microphony and self static vibrations. Both phenomenon modulate the

signal and are BAD.

The sign of good cap as I said before is

tight radial winding, (no soft

belly) and heavy weight.

Types

There are two general types of capacitors: "electrolytes" and "foil".

The

former type has polarity and you will see a plus sign or any other dot,

stripe or mark showing the negative electrode. Electrolytes have very

lightweight body, and gigantic ratio of capacitance to physical size.

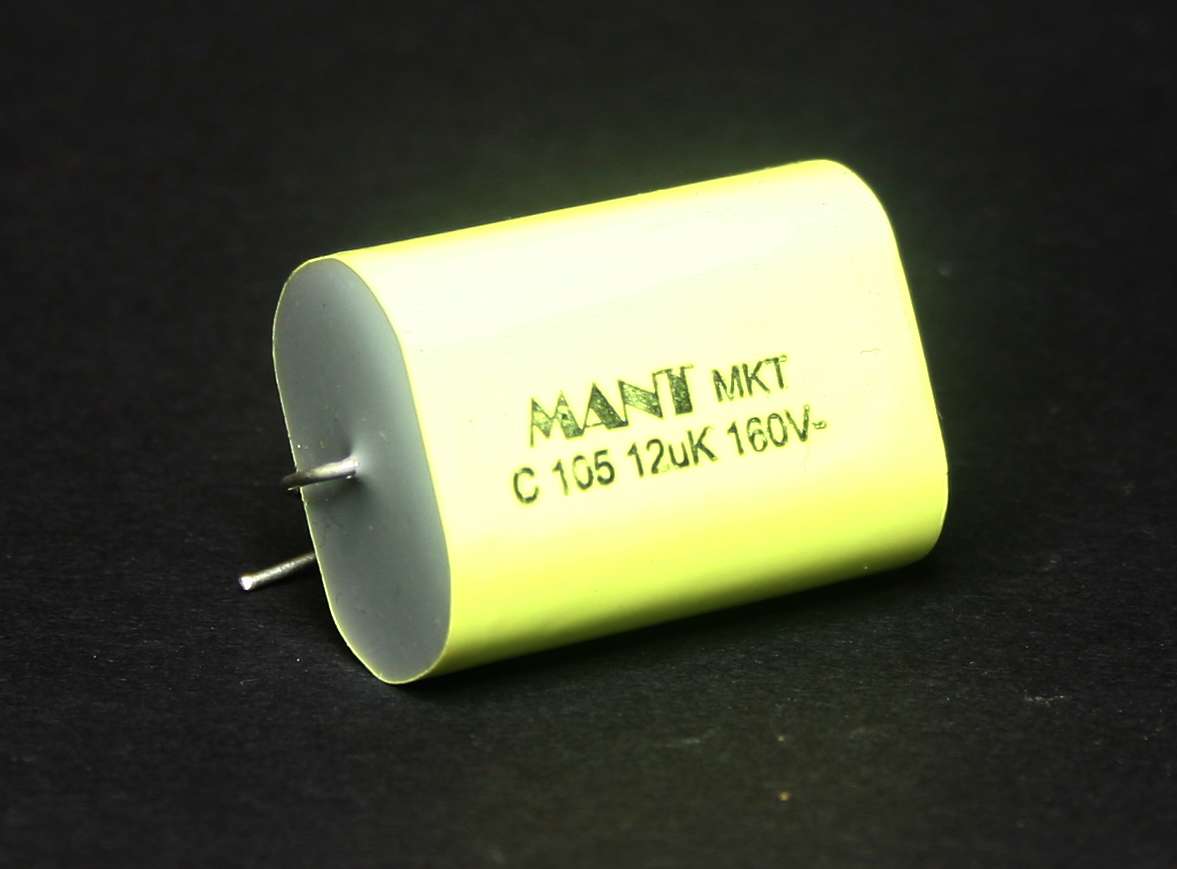

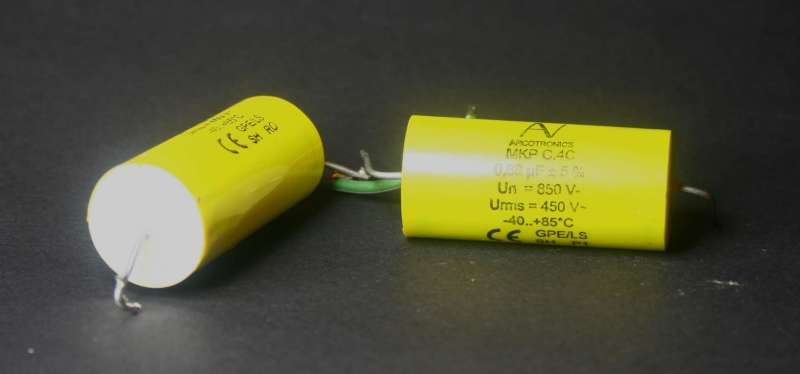

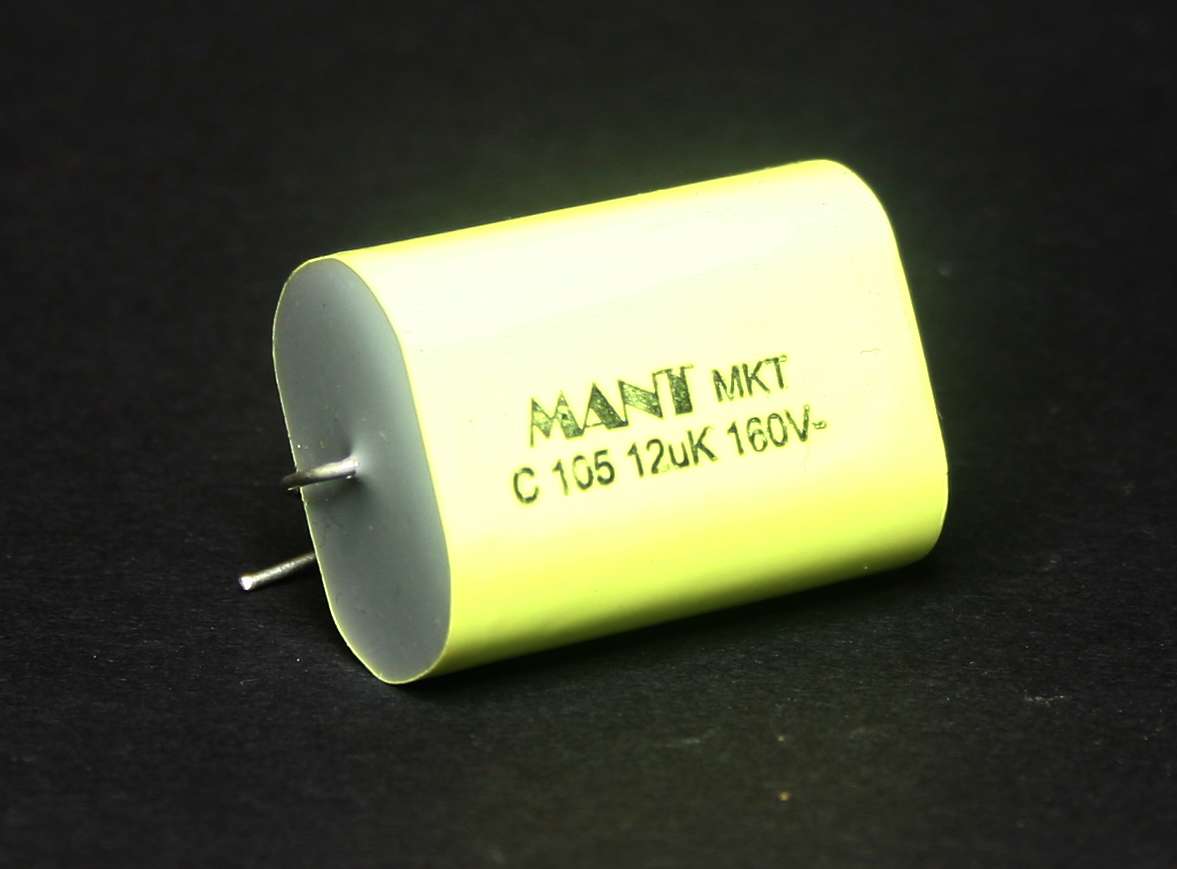

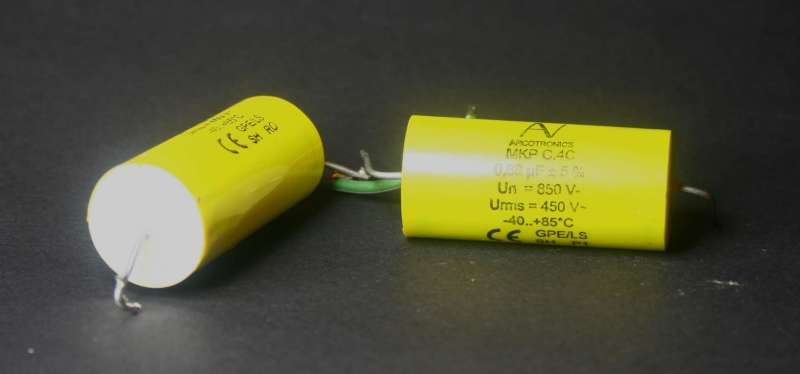

A cap of foil type and a size

of cigarette bat can not possibly have

capacitance higher than 1 or 2 uF. If it is higher - it is an

electrolyte. A cigarette bat sized electrolyte by 6V can have as much

as 3000 uF or even more.

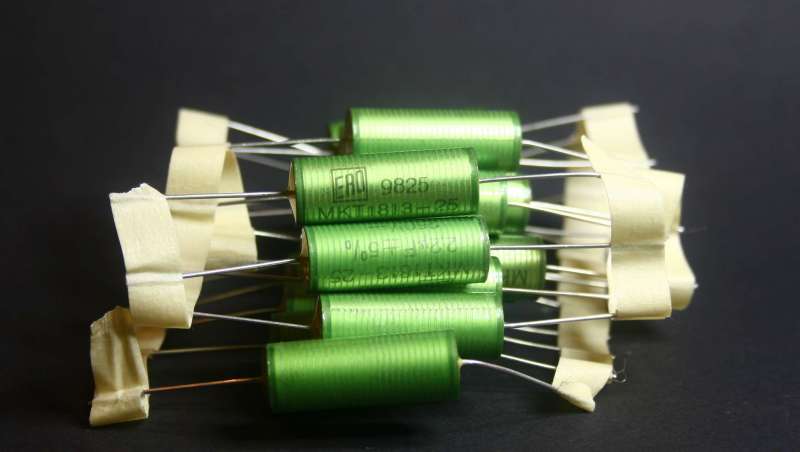

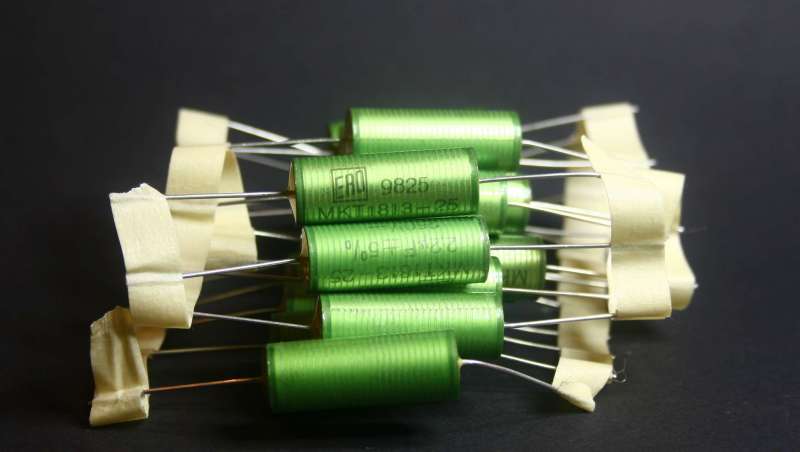

Foil types are sub divided by the electrode material. The better one is

METAL FOIL. Like baking foil or chocolate wrap. This electrode type is

heavy, rare to find, expensive and physically thick. But it makes best

caps, where high currents can flow at small resistance. A prime example

is an absolutely adorable coupling cap COPPER FOIL PAPER IN OIL by

Jensen or Audionote. All things being equal and considering not

stratospheric price - probably the best choice of signal cap.

A cheaper idea is to deposit metal vapours directly on dielectric

foil. In that scenario the insulator is the same, but the

electrode has no "body" It is

one atom layer thick. It saves space but sounds less highend (well most

of the cases - but not all). It sounds kind of "dry".

Shapes

For mass mounting convenience of robotized assembly lines caps

were forced to take all kinds of cubic shapes. THIS IS WRONG. A

cap is a ribbon wound onto itself. If the core on which it is wound is

a flat rectangle - it will end up with uneven tension. High

winding tension

on the edges, small tension in the side cheeks. It becomes an ONION.

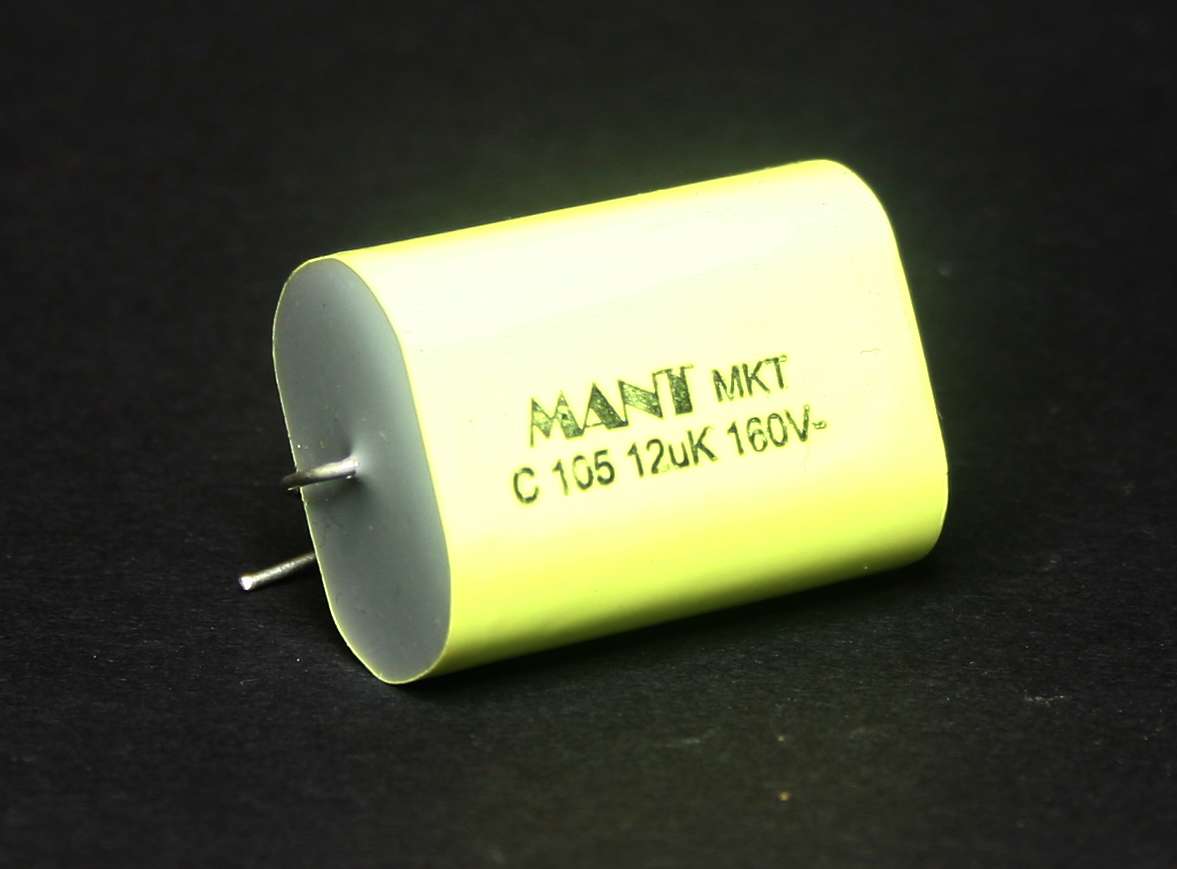

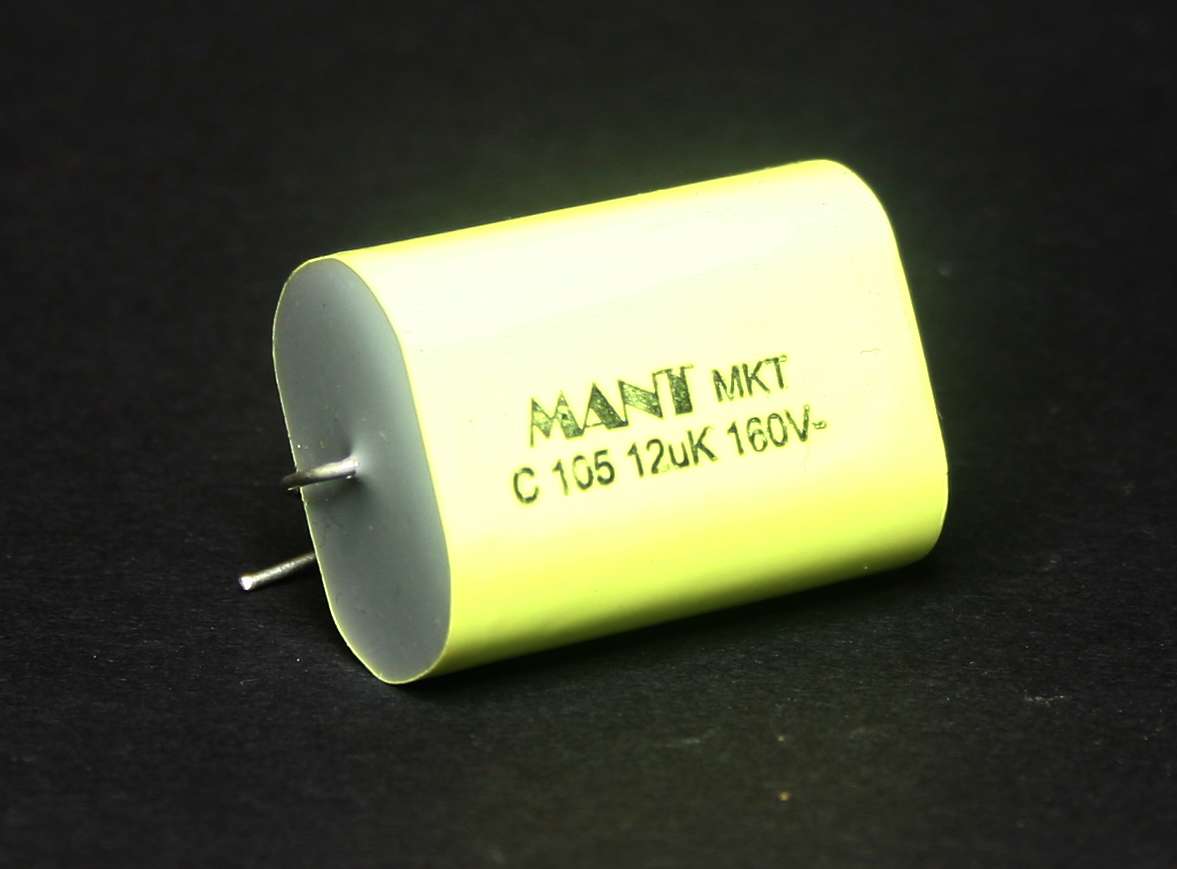

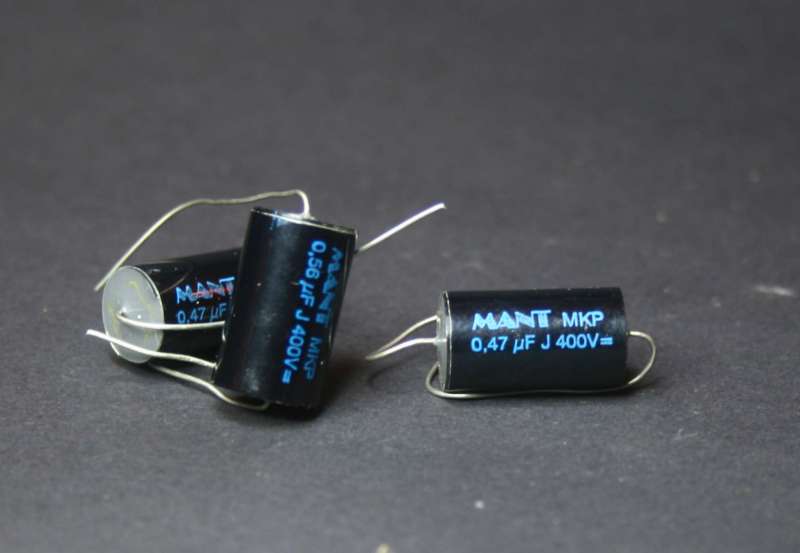

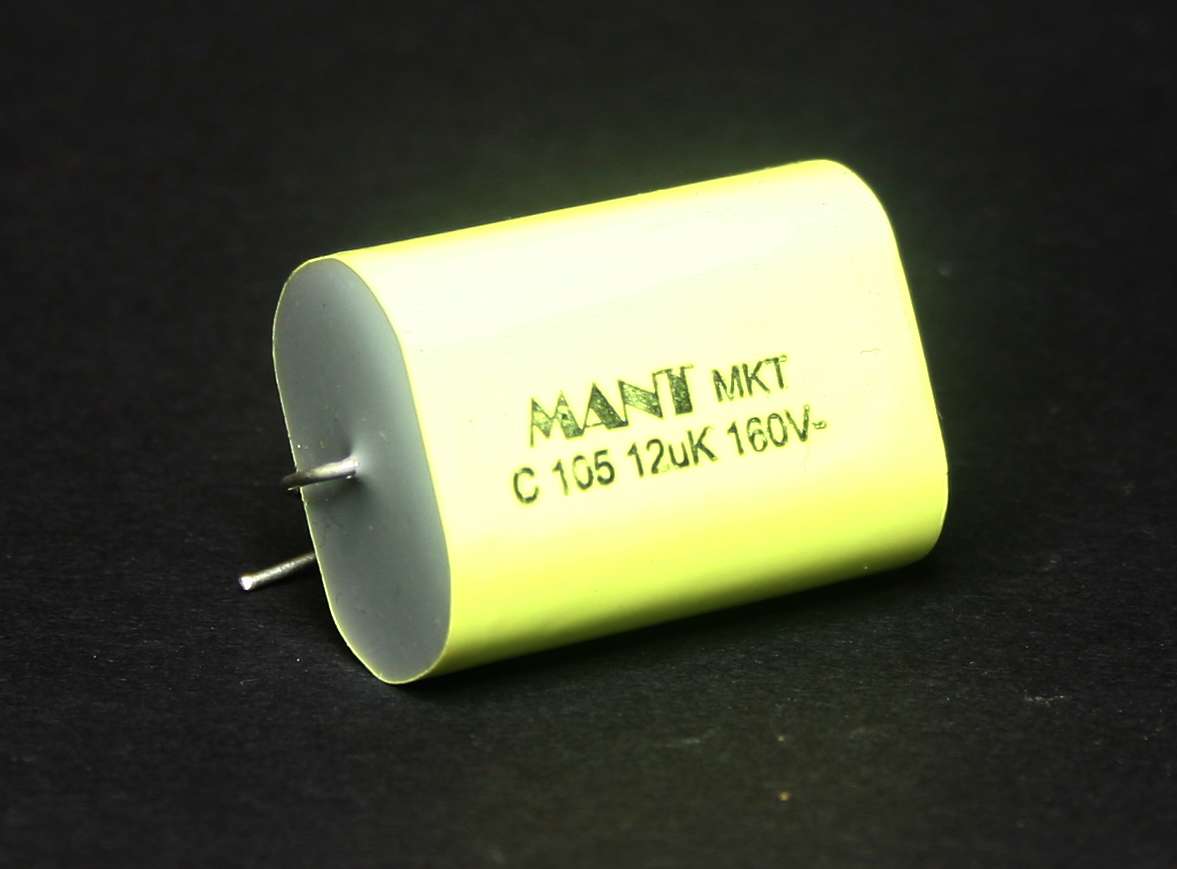

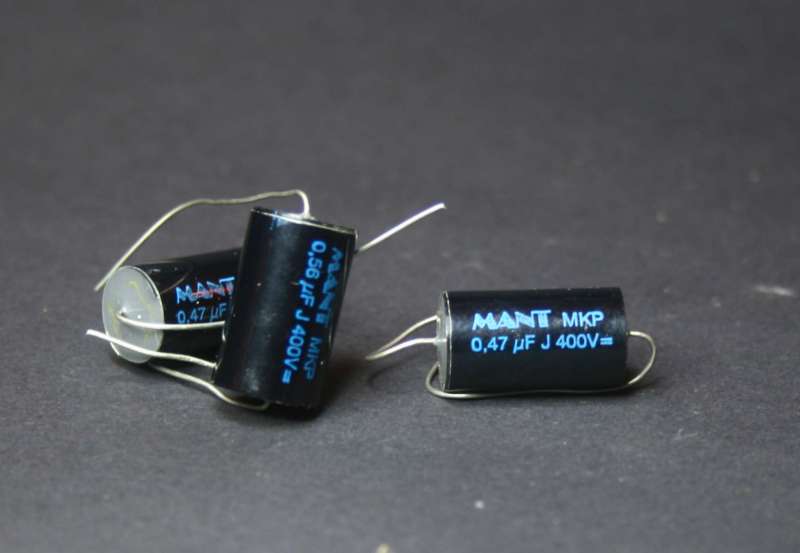

THE ONLY PROPER WAY of winding is RADIAL and round, cylindrical shape

with equal and controlled tension. That makes a GOOD CAP. Stay away

from cubes and other non cylindrical forms. Many high end caps like

Relcap are like that bad oval onion.

Nice round cylinders sound better and age better and do not break

easily. They are less microphonic and less self flexing.

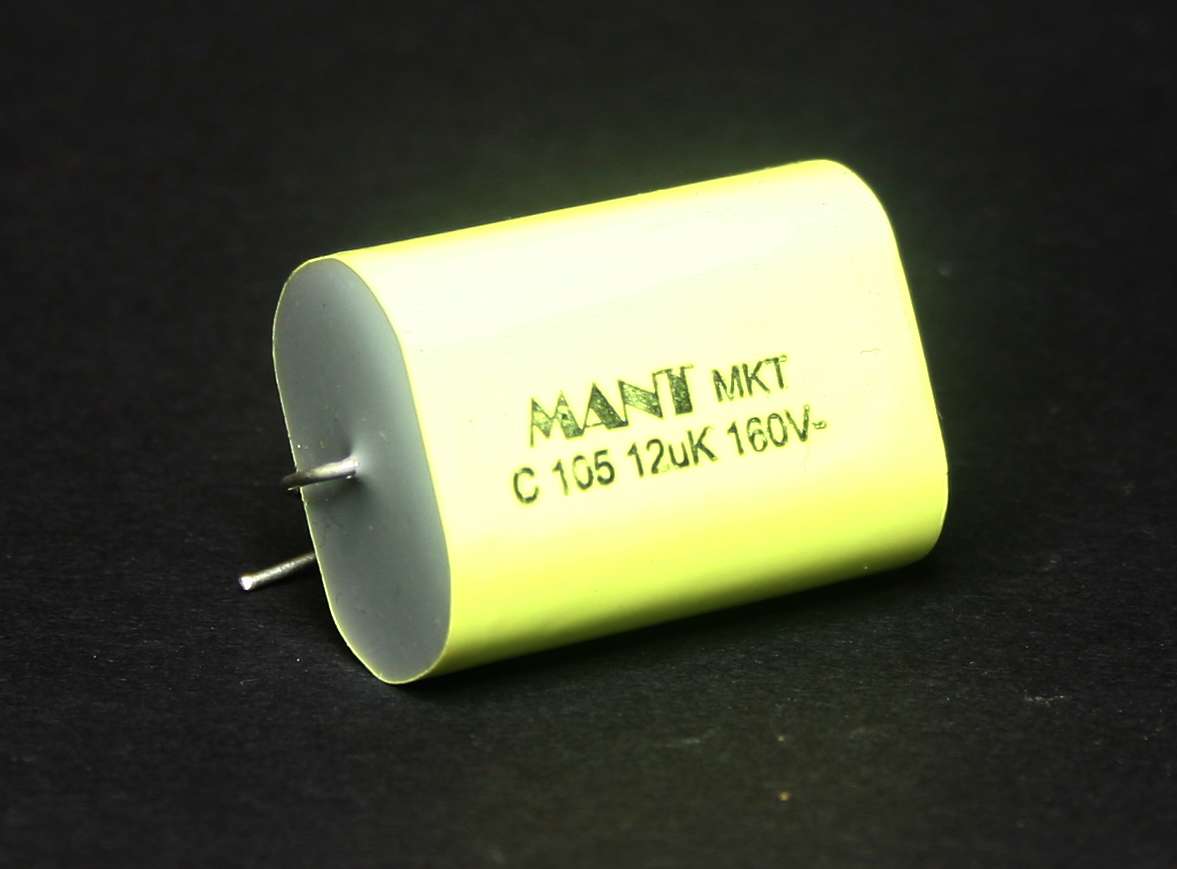

BAD - Stadium shape

GOOD SHAPE

Another good indicator of quality is when the cap is hard. Softly wound

caps which you can squeeze and deform by fingers - are BAD CAPS.

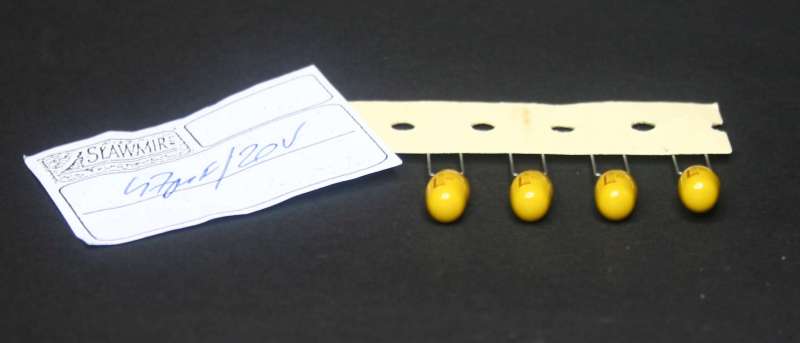

Tantalums are strange rare breed of electrolytes, and they have some

great properties and some less great properties and their dosage should

be handled with care. It is easy to overdose, like with salt in the

kitchen.

For the same capacitance and same voltage I will choose a physically

larger cap over a smaller cap. I will choose heavier cap over lighter

cap. I will choose round wound cap over a stadium shaped, elliptical

one

or a cube.

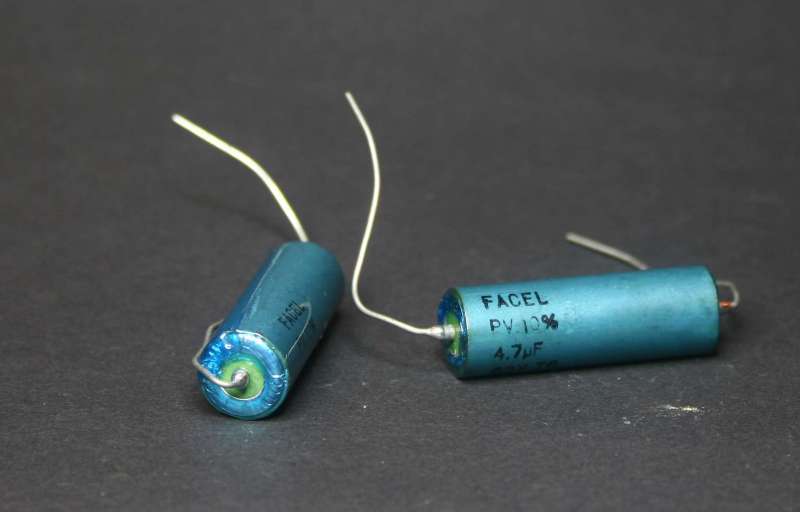

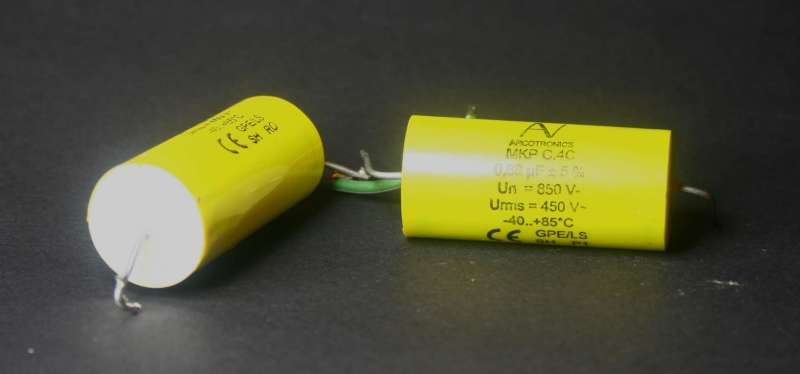

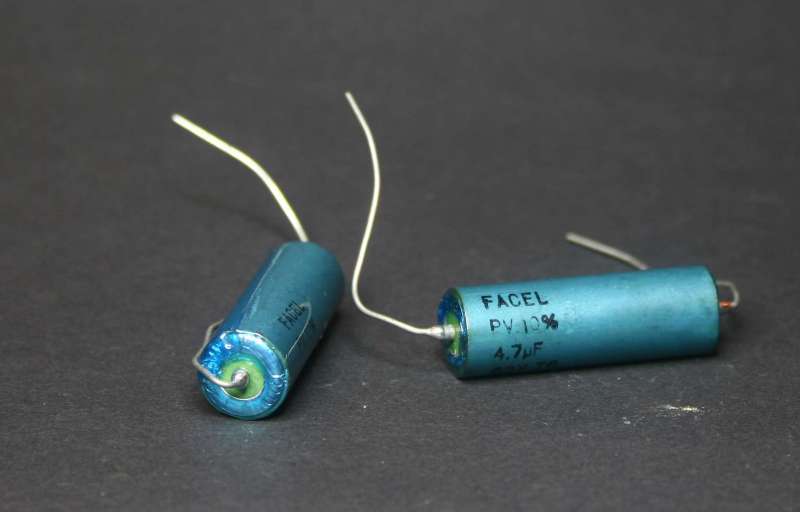

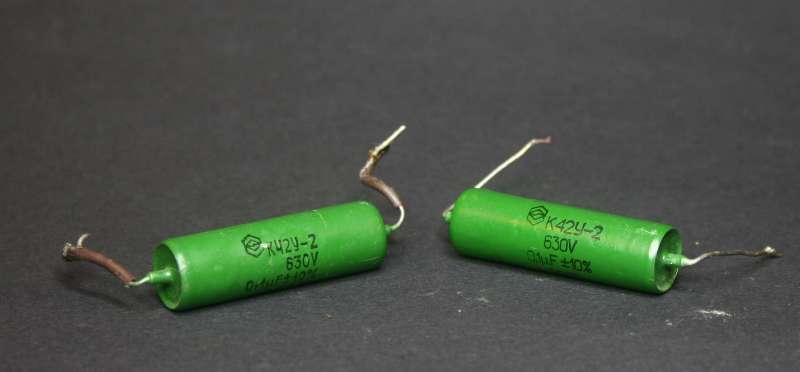

A very rare but audiophile approved sub type of foil cap is PIO which

stands for paper in oil.

The electrodes are just a metal foil, usually aluminium, sometimes tin,

and rarely copper or even silver. So the first parameter is fulfilled -

electrode is not vapour deposit but real metal sheet.

The dielectric or insulator in this case is PAPER, and correctly

speaking - cellulose. It is very pure chemically and it is slightly

porous. To improve heat dissipation, to prevent paper oxidation and to

heal possible breakage of paper - the cap is submerged in special

transformer grade mineral or organic oil. But contrary to popular

belief -

oil is NOT THE INSULATOR.

Due to preservative qualities of the oil - no metal oxidation, no

paper drying out - PIO tend to live 50 years or more.

One of the reasons they sound good is that when voltage is applied,

electrostatic forces cause the layers of foil to expand and contract,

to BREATHE. This is dampened by the oil . The minuscule internal

vibrations are eliminated. The cap sounds SMOOTH.

APPLICATIONS

decoupling

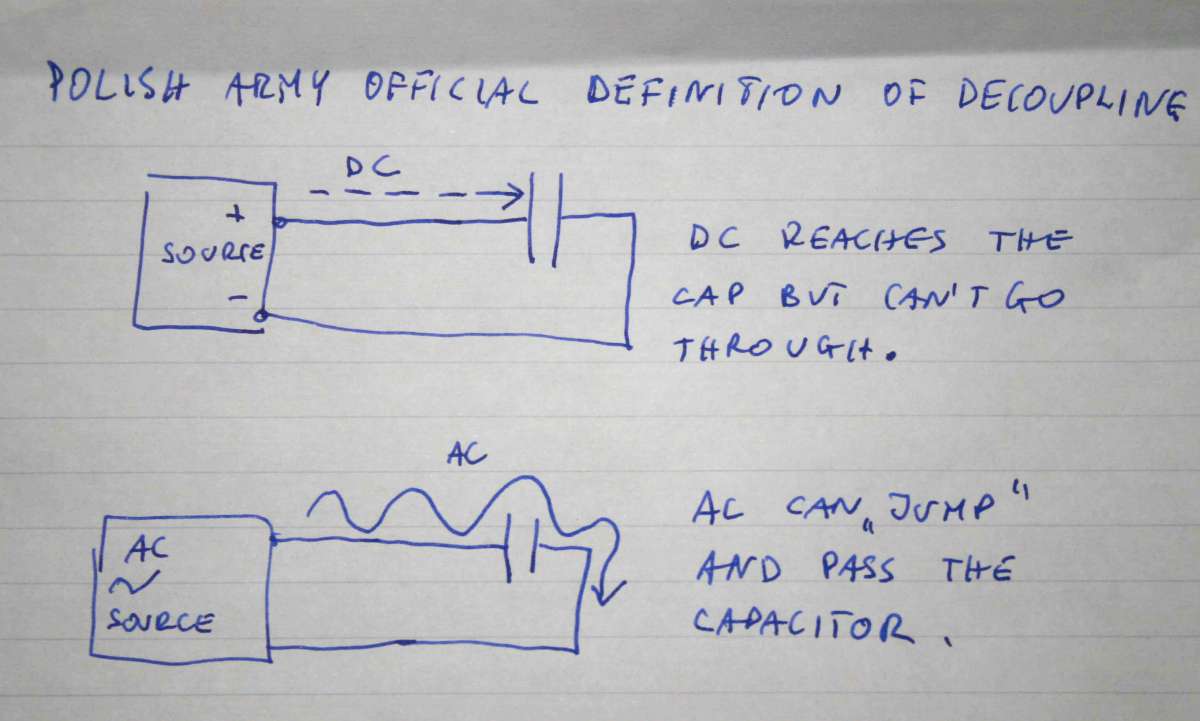

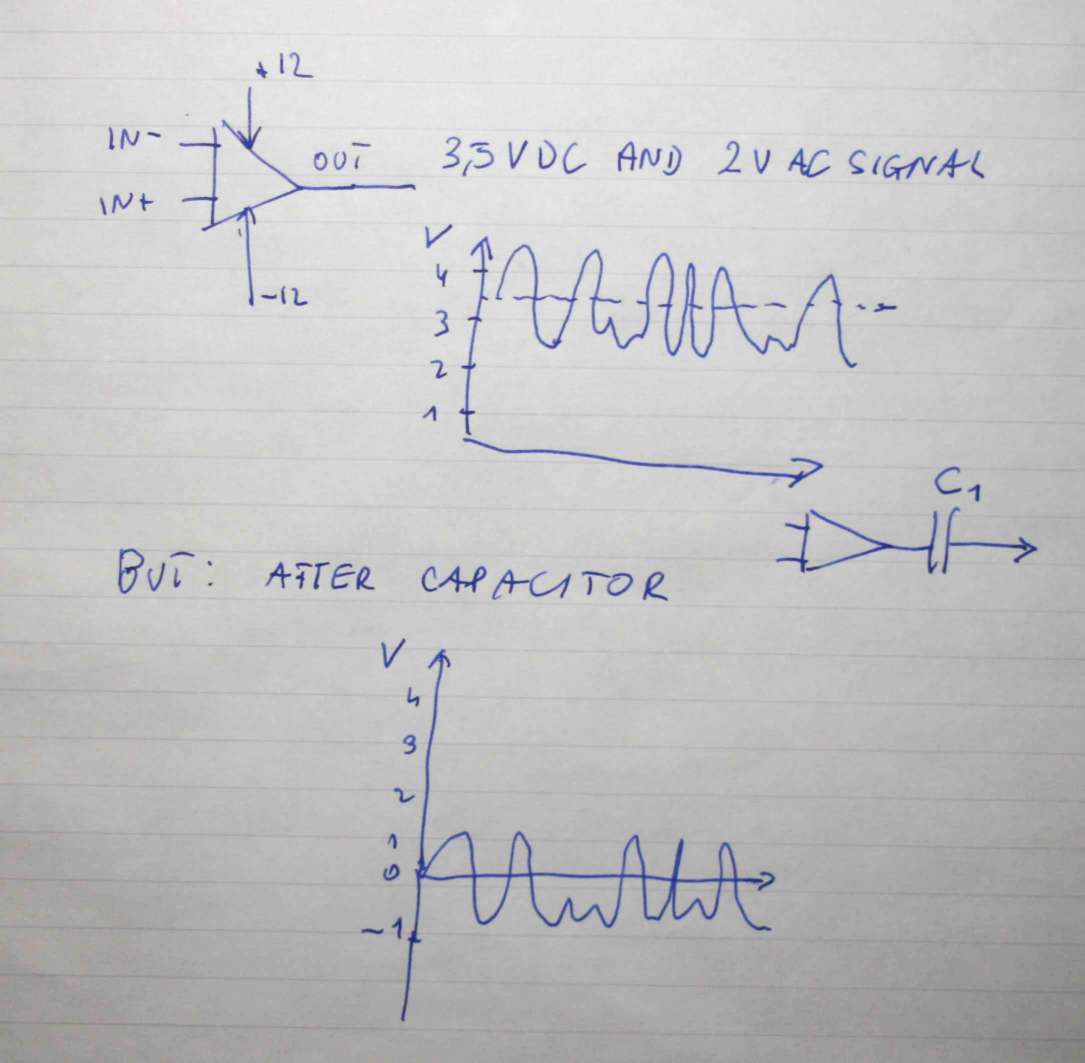

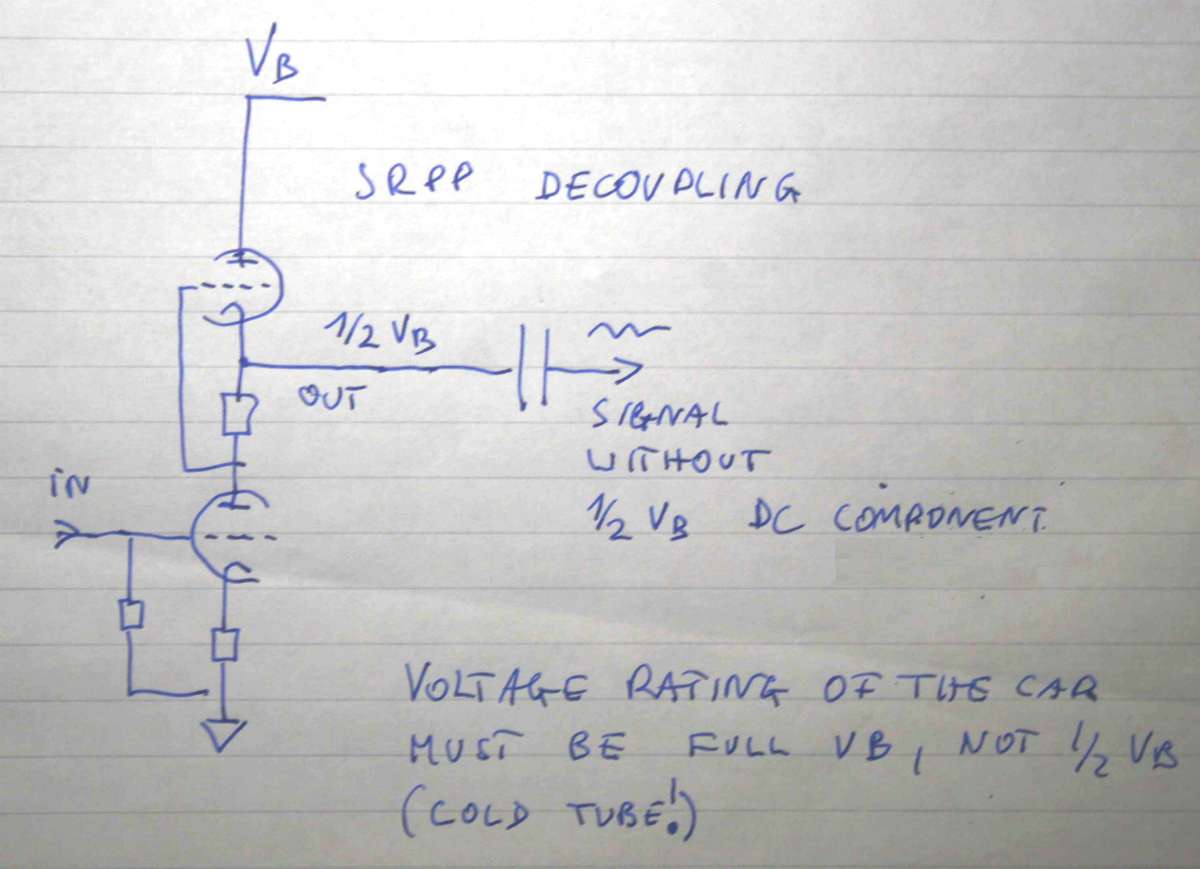

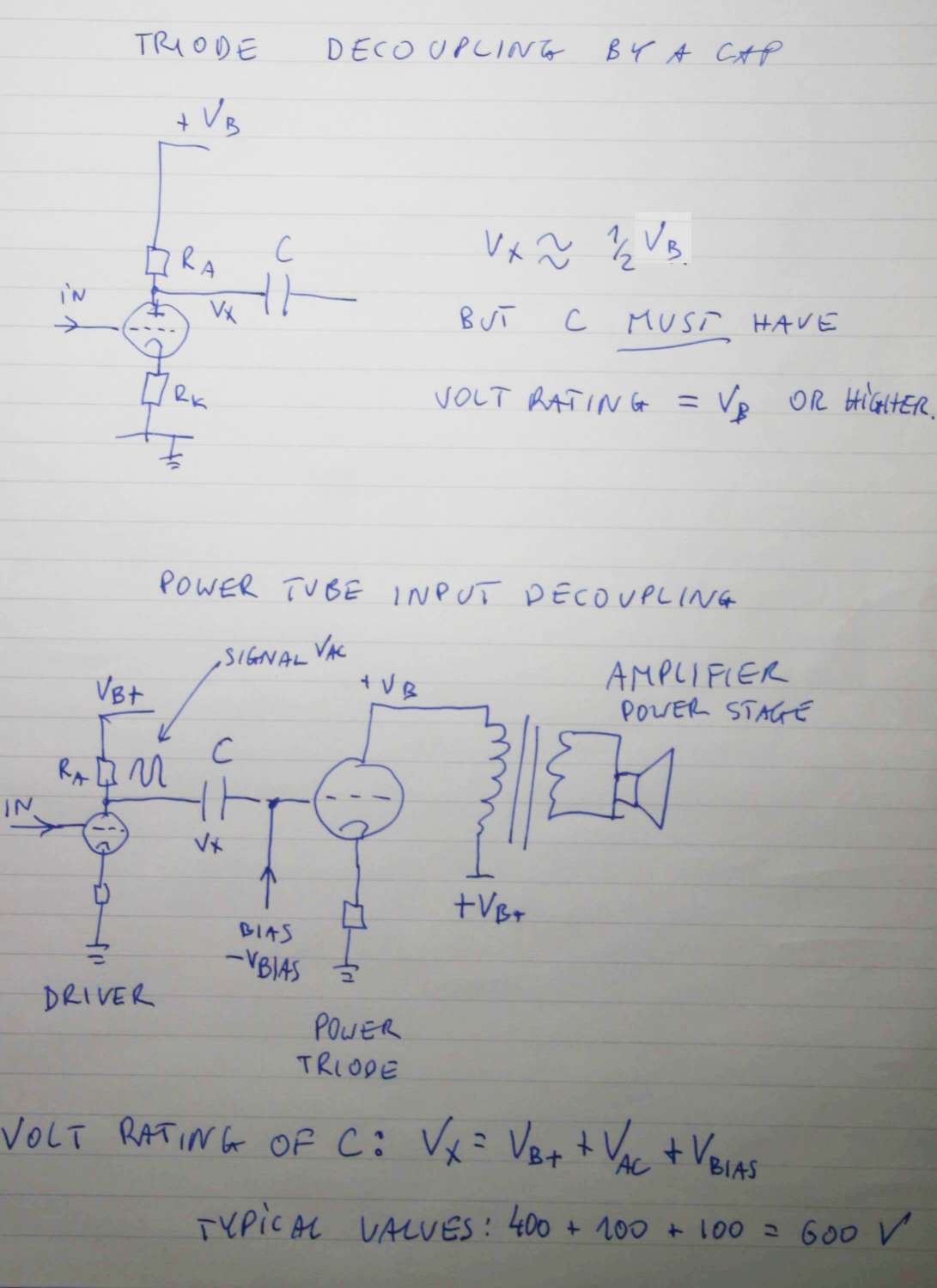

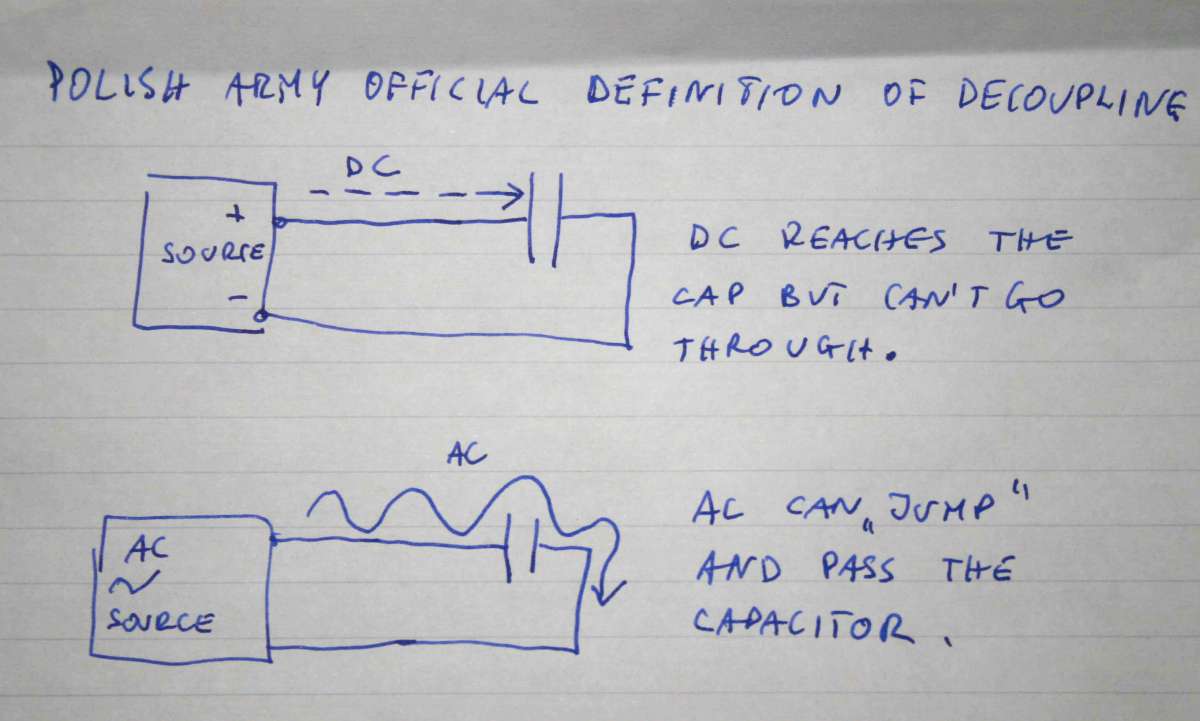

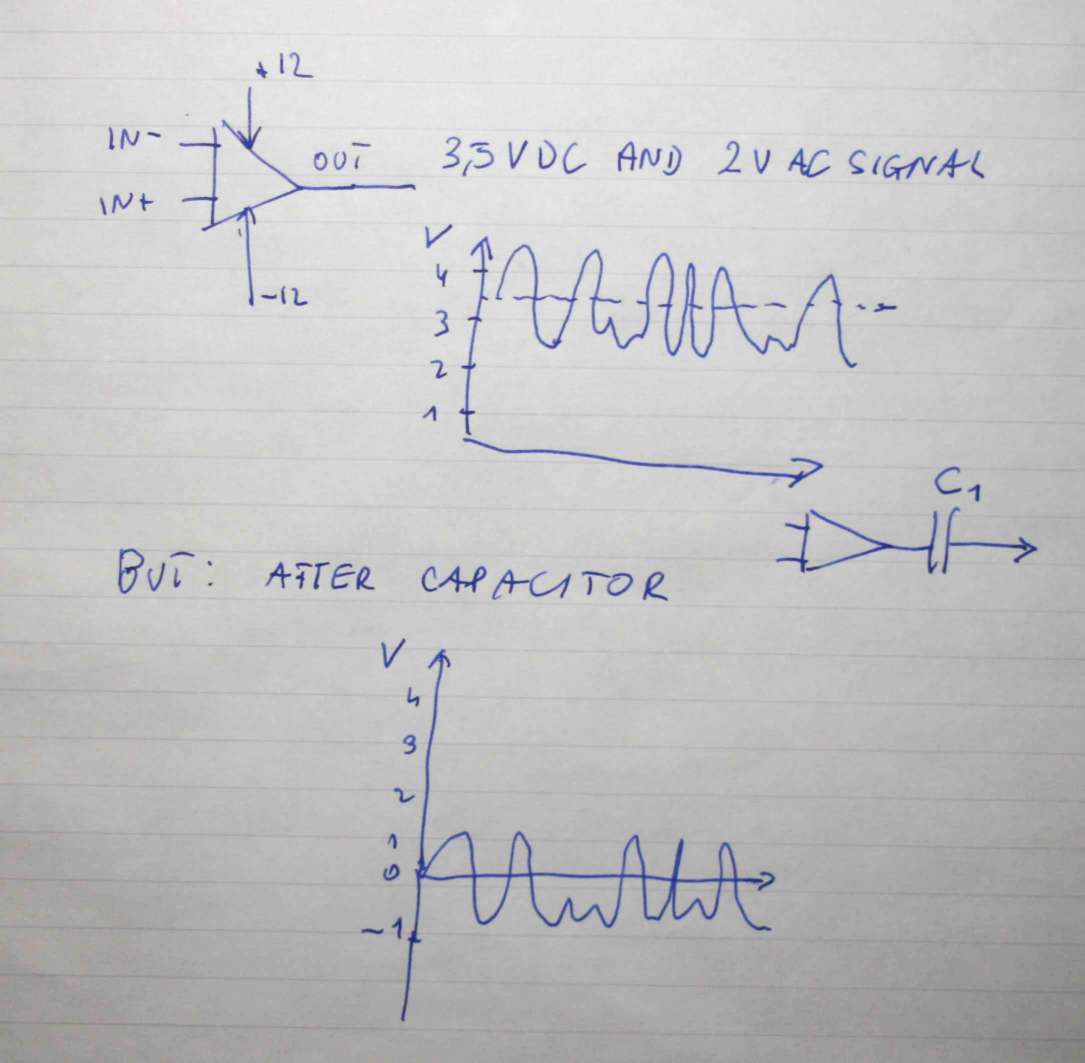

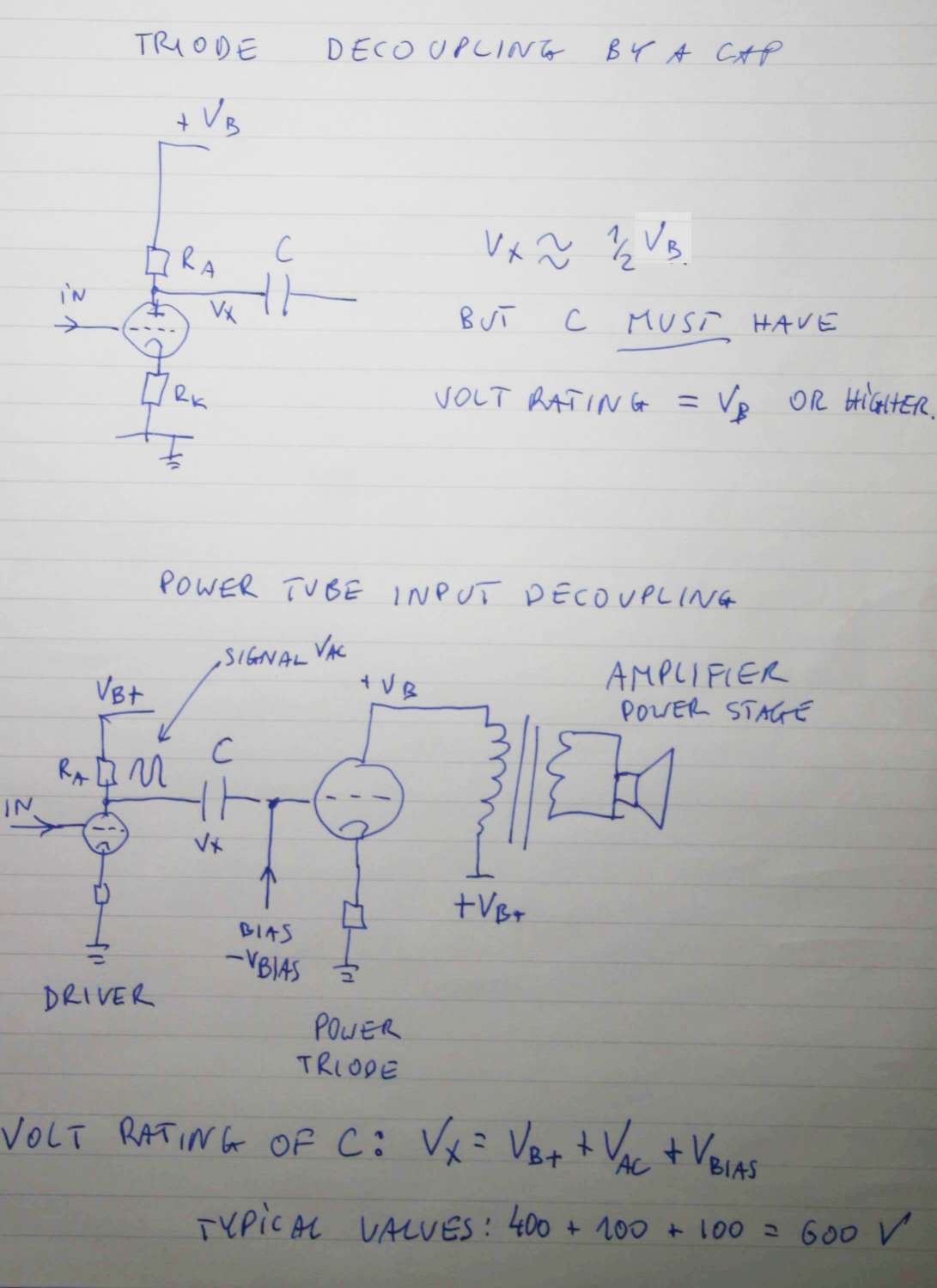

Decoupling is a series application of a cap where on a given line is a

combination (a sum) of DC as a power supply by-product and AC as

a

signal.

At the output of tube amplifier stage there may be on the wire say 150

VDC as a result of triode "modus operandi". At the same time our

musical signal is only 2 V alternating, so relatively small. We need to

block the DC and pass through only the music. That is called

decoupling.

It is like the window: it stops the wind but passes the vision through.

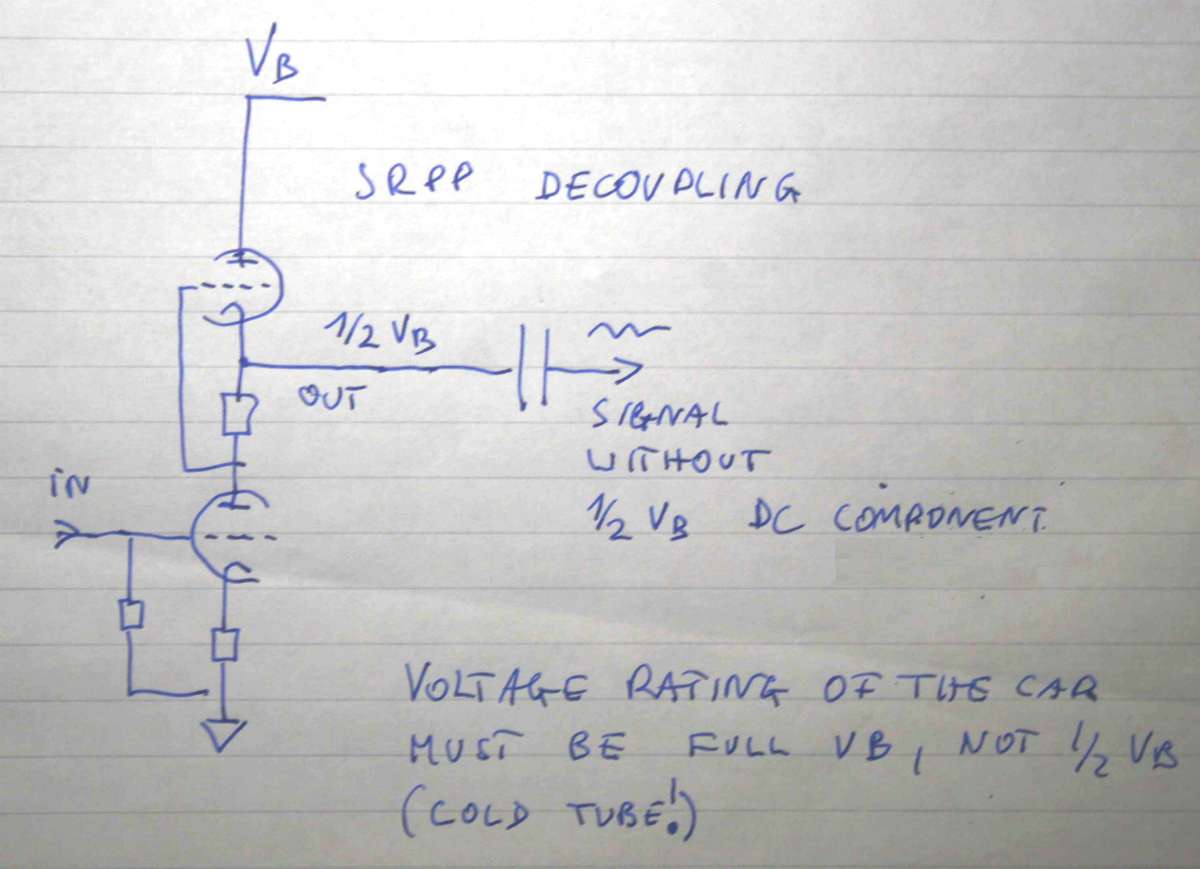

So decoupling caps must have VOLTAGE RATING higher than the "left hand

side" DC plus the peak of the signal plus the right hand side

negative DC - like in power tube bias..

If the power tube driver triode has 200 VDC at the output and it swings

50 V pp of our music and after the capacitor is the grid of power tube

with -60 V of bias, the minimum voltage rating of the decoupling cap

must be 200 + 50 + 60 = 310 V. It is safer to put instead of the first

figure ( - the 200 V -) the full B+ (power supply) of the whole

small tube

section (usually 400V). That is because when tubes are cold, the tube

current does not flow, the anode resistor does not drop voltage but

passes all through. The same happens if heaters fail, or if cathode

resistor burns. So our worst case scenario is B+ plus music at full

volume plus bias of power tube.

In CD players - the decoupling function is usually applied over

relatively low voltage:

Voltage Output DACs have 2,5 VDC offset - meaning - steady DC always

present at the output.

Opamps have between 1,5 and 3,5 VDC offset. Maximum 10. (extreme figure)

So voltage of decoupling caps is unimportant - every cap in existence

will be OK.

But what about the SIZE for decoupling? Does it matter ?

In decoupling role the cap acts as decoupler but also as a first order

hipass filter. It means it will have a "knee" at a certain low

frequency. When will this KNEE interfere with our music?

It is frequency dependent and LOAD dependent. Our cap will have the

knee at a point depending on the IMPEDANCE IT WILL SEE AFTER

If the device after the cap is say a tube grid, we can calculate

the knee for 250K impedance load. That is VERY VERY high impedance load

which means it is VERY VERY easy to handle which means the knee of a

0,22uF capacitor will be VERY VERY low, in the range of say 1/2 Hz.

Even bass freaks and audiofetishists will admit, that 1/2 Hz happens in

our music quite rarely. Even at Dead Can Dance intro and Massive

Attack's "Mezzanine".

If the load to the circuit is the next AMPLIFIER, we assume the amp has

a 100K pot. Or 47 KOhm pot. So our knee will move up 5 times, and it

will affect bass notes at 2,5 Hz. Still low.

Knowing all that, we will no longer bother Mr. Lampizator with

questions like "will 2 uF for

Lampucera decoupling be good, or will 5 uF be better? Will 1 uF be much

too small?"

OK, I admit that some 5 uF caps sound better than some 1 uF caps

but that is not because of the size difference, but because different

build dictates different sonic signature due to inductance,

inter modulations, microphonics, and series leakage. But there is no

human who can hear a 1 uF difference PER SE.

Remember, as we increase the cap size we move maybe the bass knee below

1 Hz but the upper frequencies will start to see the second knee -

treble knee. resulting from increasing impedance at increasing

size. That's why BIGGER IS NOT BETTER and the cap must be within the

limits

of sanity.

Back to the window glass example - all glass thickness will do their

job well - will block wind. a 1 mm glass will do it equally well as 2

mm and equally well as 4 mm and 10 mm.

Only at the extremes, the glass will be too thin (below 1 mm) or too

thick (above 20 mm it will look greenish and ugly). And it will be

unnecessarily bullet-proof.

So if you just try a decoupling application in a project, and you have

a shallow drawer of caps, the 100nF MKP will be as good as 200 nF MKT

and a 10 uF tantalum and a 100 uF electrolyte. They will all decouple

equally well.

After the project is successfully finished, you may want to shop around

the internet for optimal PIO caps or something like that.

Summarizing - as a rule - there is NO AUDIO APPLICATION OF DECOUPLING

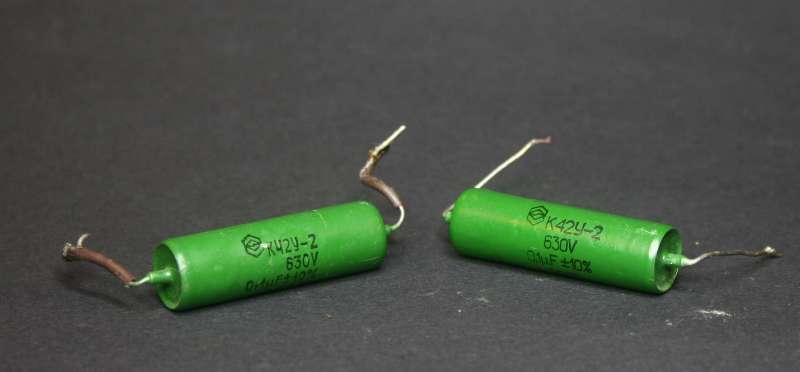

where a 1 uF

foil type cap with 600 VDC rating would not fit perfectly. Always keep

a handful of these in your drawer. My favourite caps of sane price are

SCR KP-SN tin metal plus polypropylene. They are just great at around

10 EU apiece.

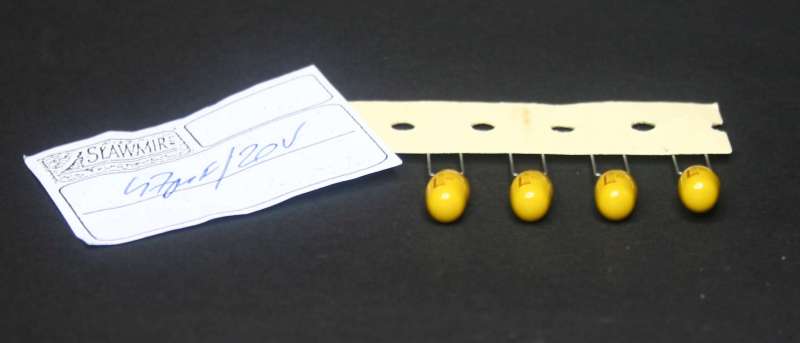

Caps as noise filters

Noise filters are caps which short high frequencies to ground. They

have no other goal in life, no other business target than BEING

OF LOW SERIES IMPEDANCE.

That's why ceramic caps are best - they pass easily megahertz without

sweat. Usually to be good RFI filters - caps must be small. Picofarads

or 1nF maximum. The lower passband of such filter is controlled by many

other parameters, but generally we want it to reach on the upper

limit AS HIGH as possible.

Power supply filters

Power supply is the opposite filter to the noise filter. While noise

filters operate at and above hearing upper limit, the power supply caps

have a role of filtering voltage fluctuations - at and below lower

hearing

limit.

The power supplies are presented with two challenging voltage

anomalities:

1. AC on the input of power supply is rectified into a tooth-saw

shape and this is

triangle 100Hz signal - well within hearing. The caps must filter that

AC to the ground leaving only DC. Usually CRC or better CLC filters

leave the fundamental of 100 Hz on a level below 1/1000 of nominal

power

voltage. That will be INAUDIBLE.

2. Second challenge is reservoir for peak demand from the circuit being

powered. (mathematically the two functions are the same - it is a

low pass filter) If a

tube triode receives a drum kick on the grid, it will open and conduct

more current, and this current is being asked at the power supply. It

is equivalent of negative voltage step. It must be filtered to ground

keeping STIFF DC at the cap/.

Operating at LOW LOW frequencies and high currents dictates that power

supply capacitors must be large. The larger the better ... until ..

their impedance affects high frequency performance. So again -

the larger the better but keep the type LOW ESR and add a bypass from

polypropylene to parallel the impedance at high frequencies.

A power supply cap of factory nominal value can always be substituted

with 10x size without negative consequences. Factory was forced by

accountants and their CFO to save money on caps by cutting them to the

SMALLEST POSSIBLE size they thought they can GET AWAY WITH.

And furthermore - since then - the capacitance probably dried out.

Oscillators

Oscillators are circuits where cap size DOES MATTER. Meaning that it

can't be bigger or smaller but EXACTLY PRECISELY on target because it

determines the frequency of oscillation. The caps must be of a kind

which is stable versus temperature, time, ageing, air pressure and

voltage. DO NOT MESS WITH OSCILLATORS. Leave them alone for God's sake !

CAPACITOR SHOOT-OUT GAMES

The contenders - groups:

Electrolytes:

Tantalums

PIO's

Foil types

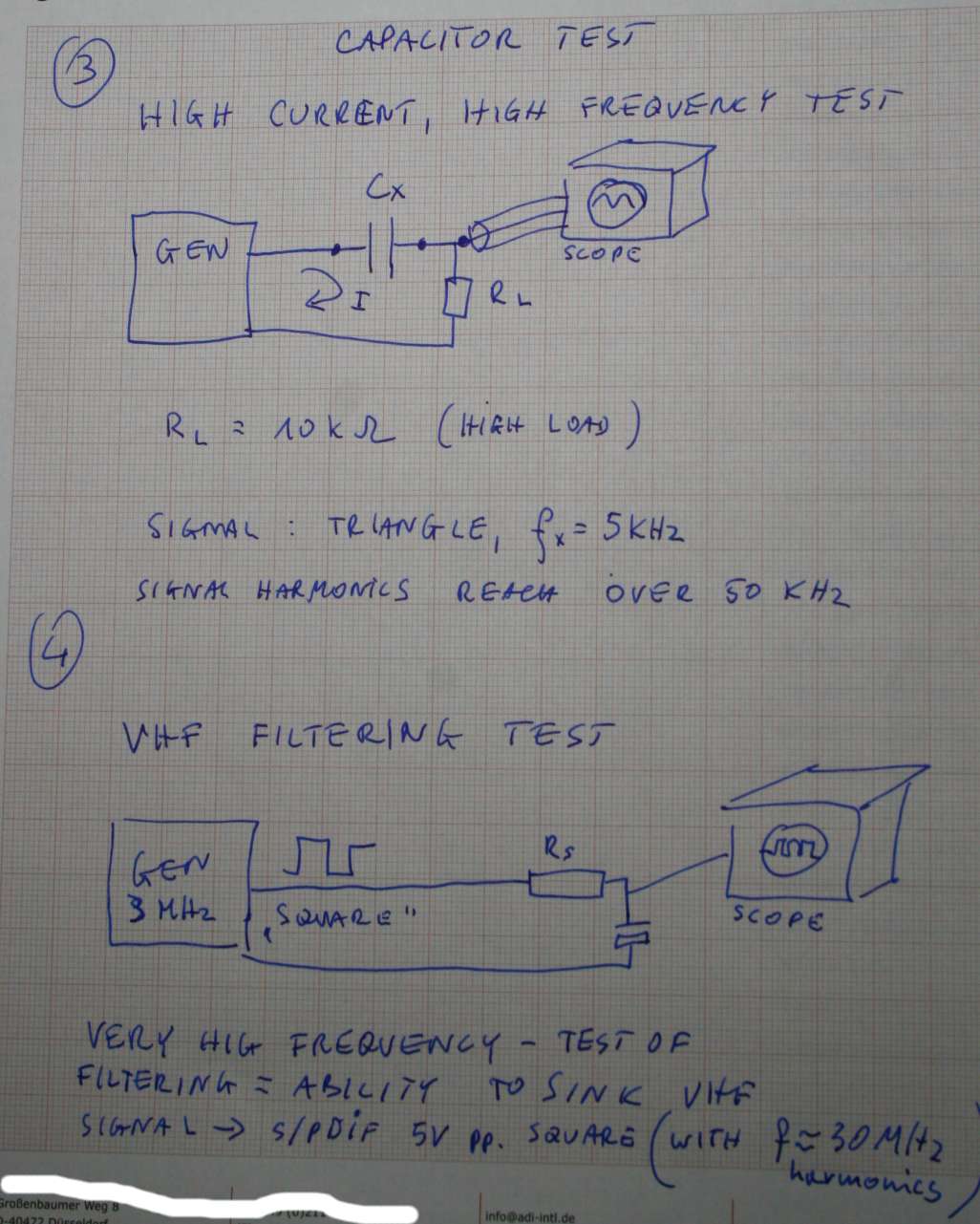

TESTING

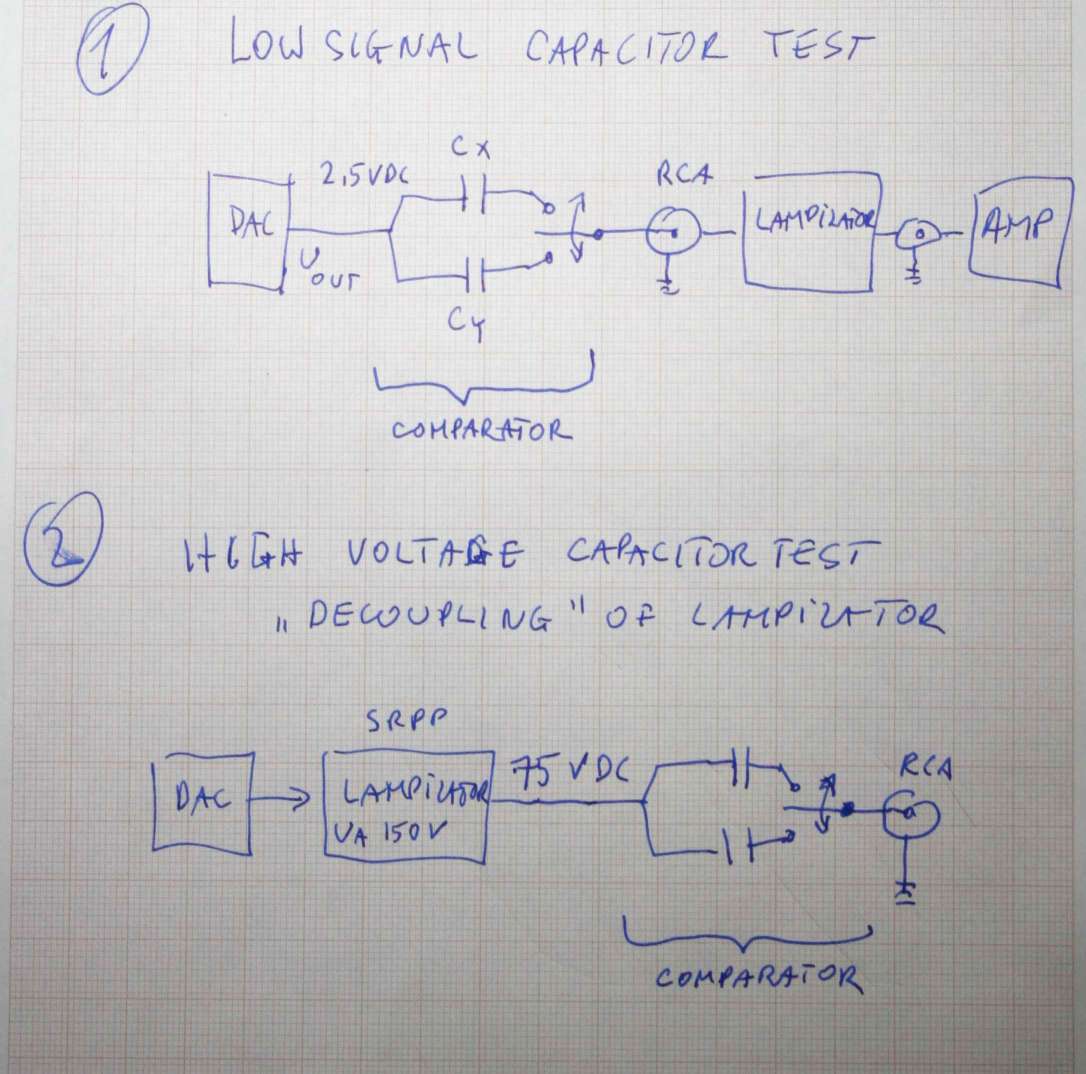

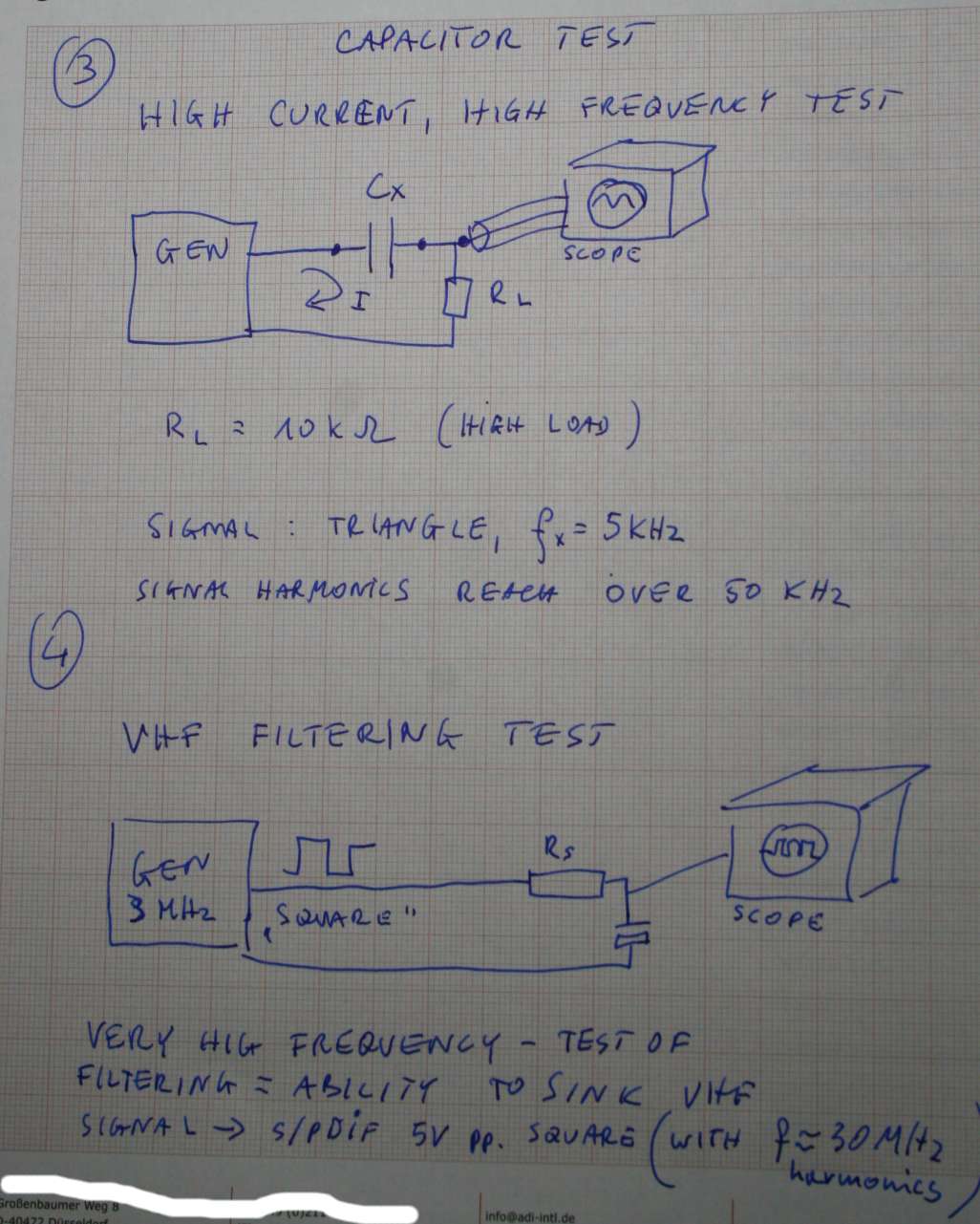

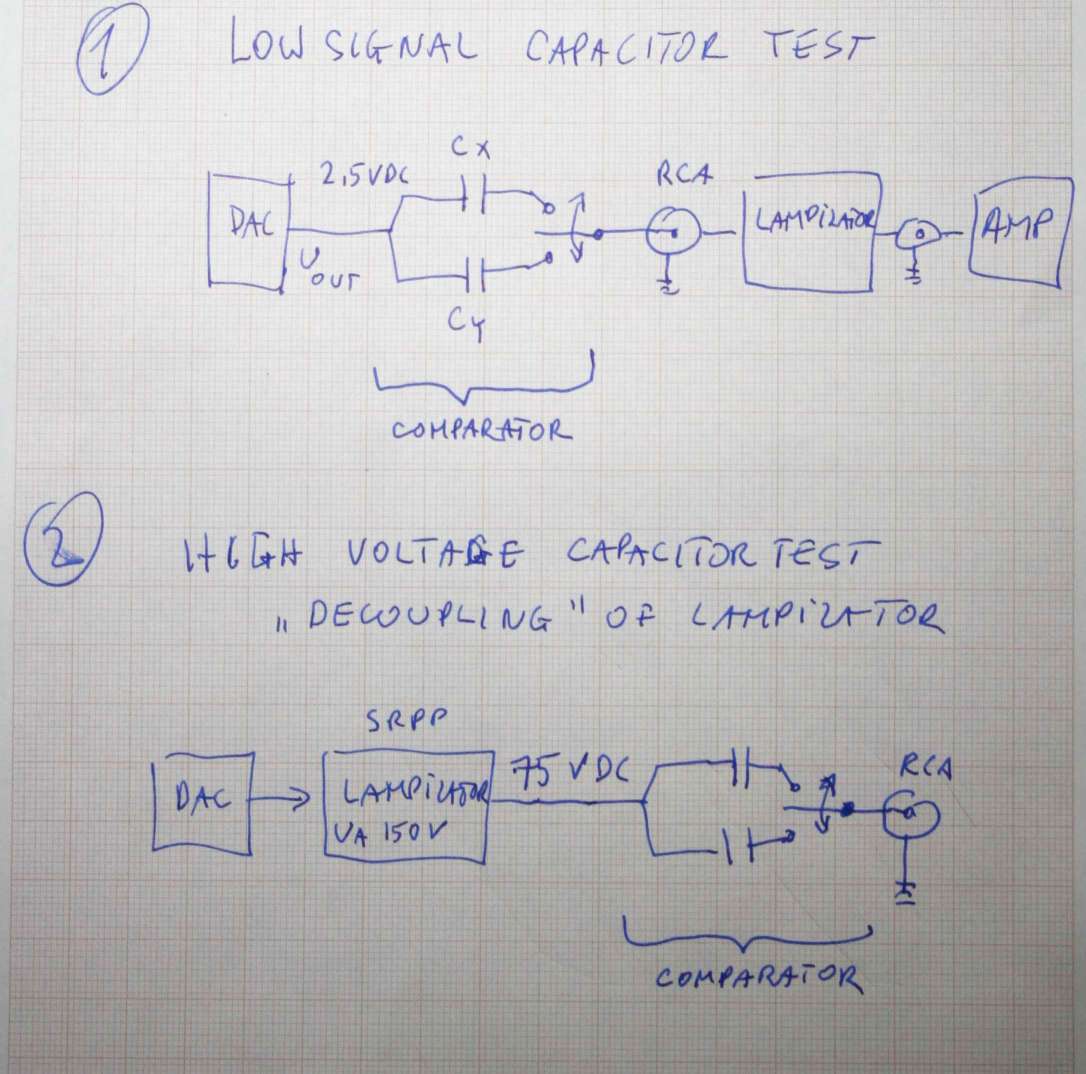

Low Voltage low current coupling test - LISTENING

Test number one: results are HERE.

TEST #2

Low Voltage HIGH current decoupling test (tweeter) -

LISTENING

Low Voltage decoupling test - MEASUREMENTS under medium load

RESULTS OF TEST

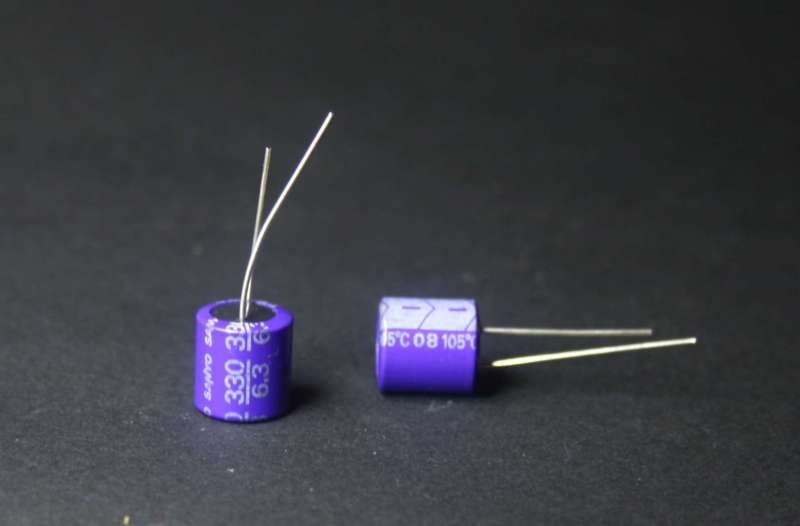

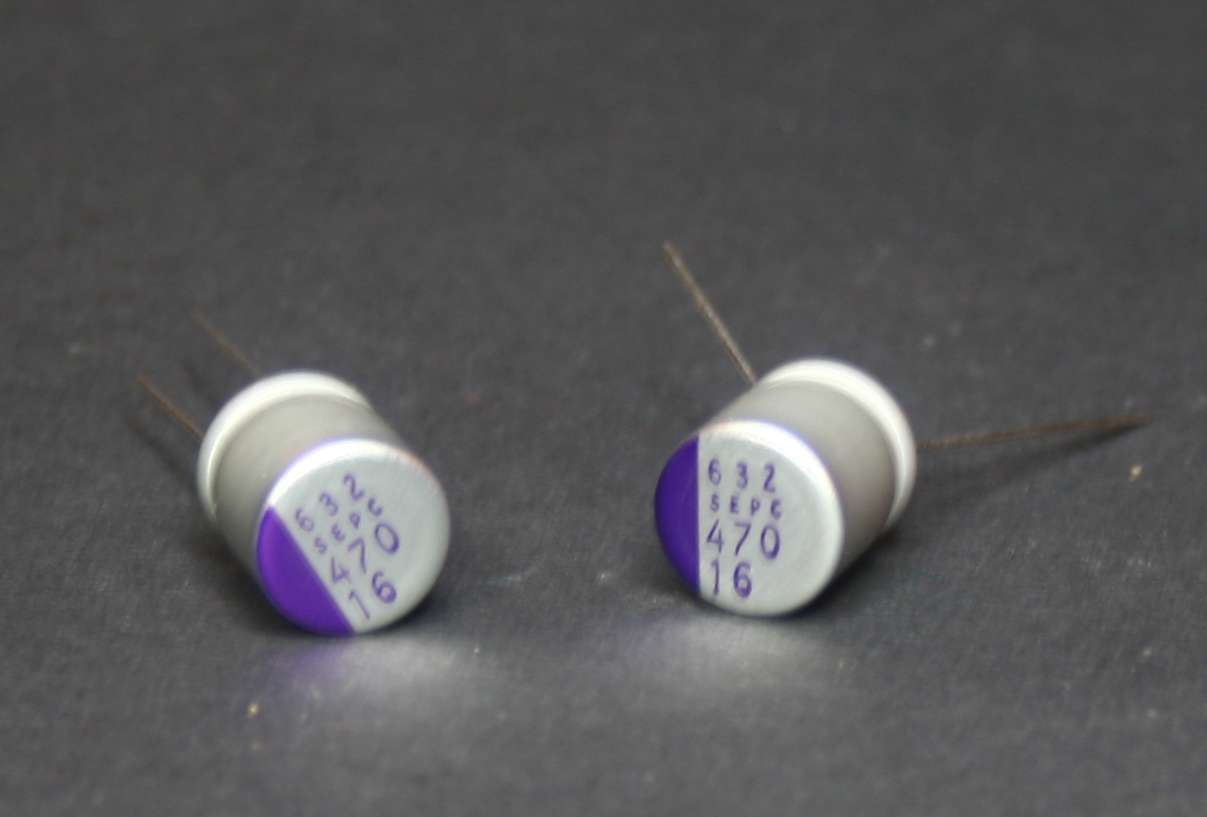

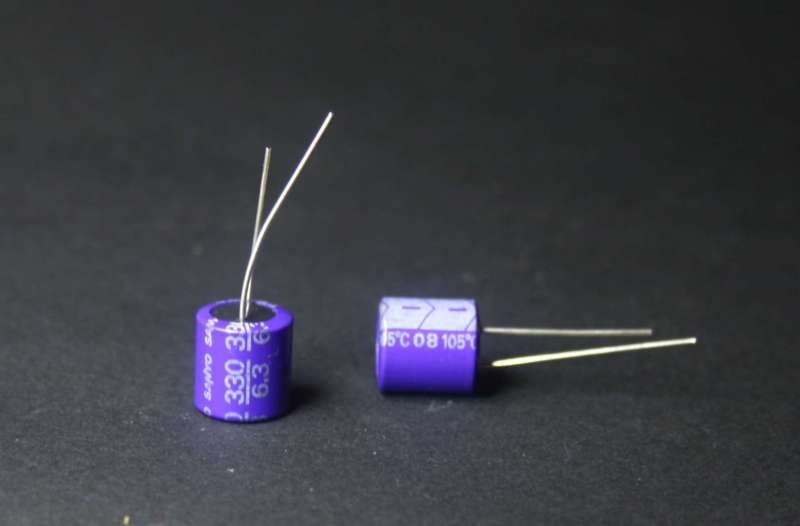

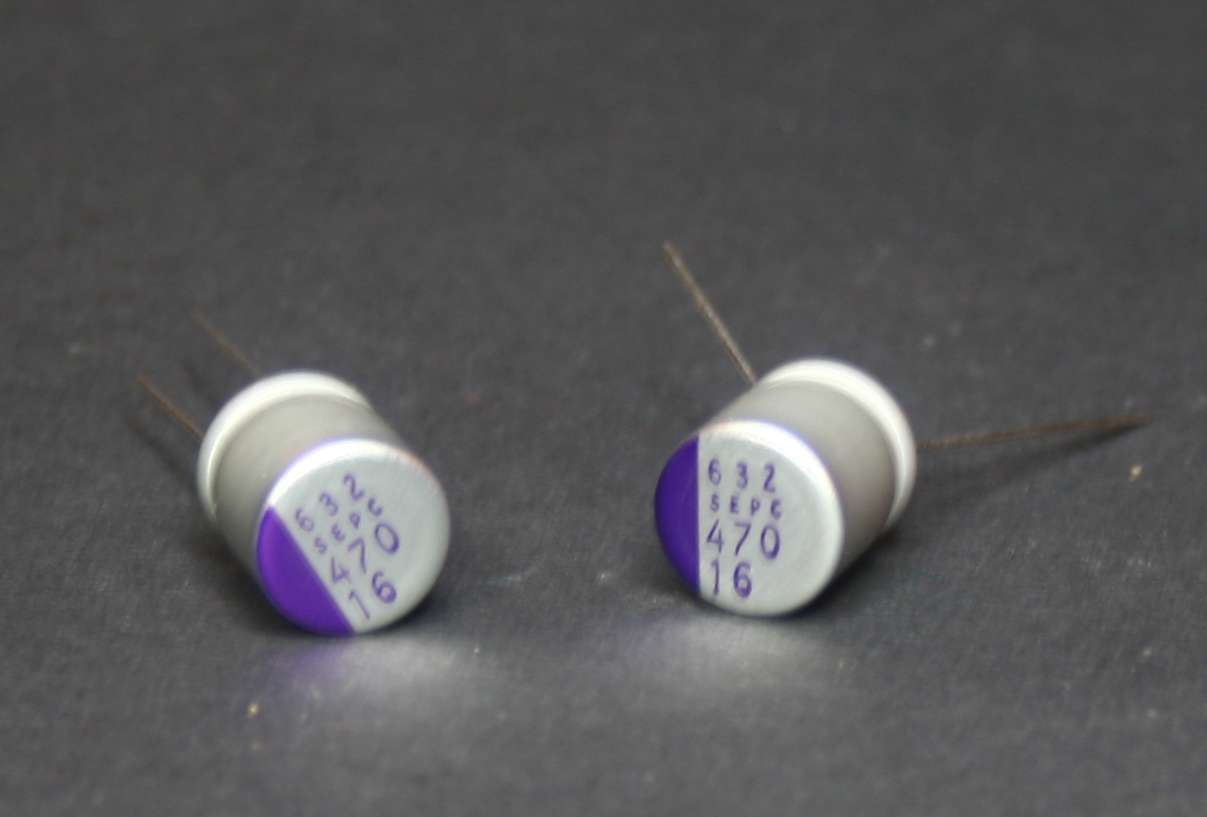

Above: the latest, the newest, the absolutely BEST oscons ever made -

SEPC generation. How about 7 mOhm ESR ???

To be continued .........